A circular packaging design consists of material selection, design strategies that eliminate waste in logistical flows, packaging lifespan, and the reuse of virgin material, while still ensuring the full functionality of packaging and stellar protection of the product.

The concept of circularity is rapidly gaining momentum.

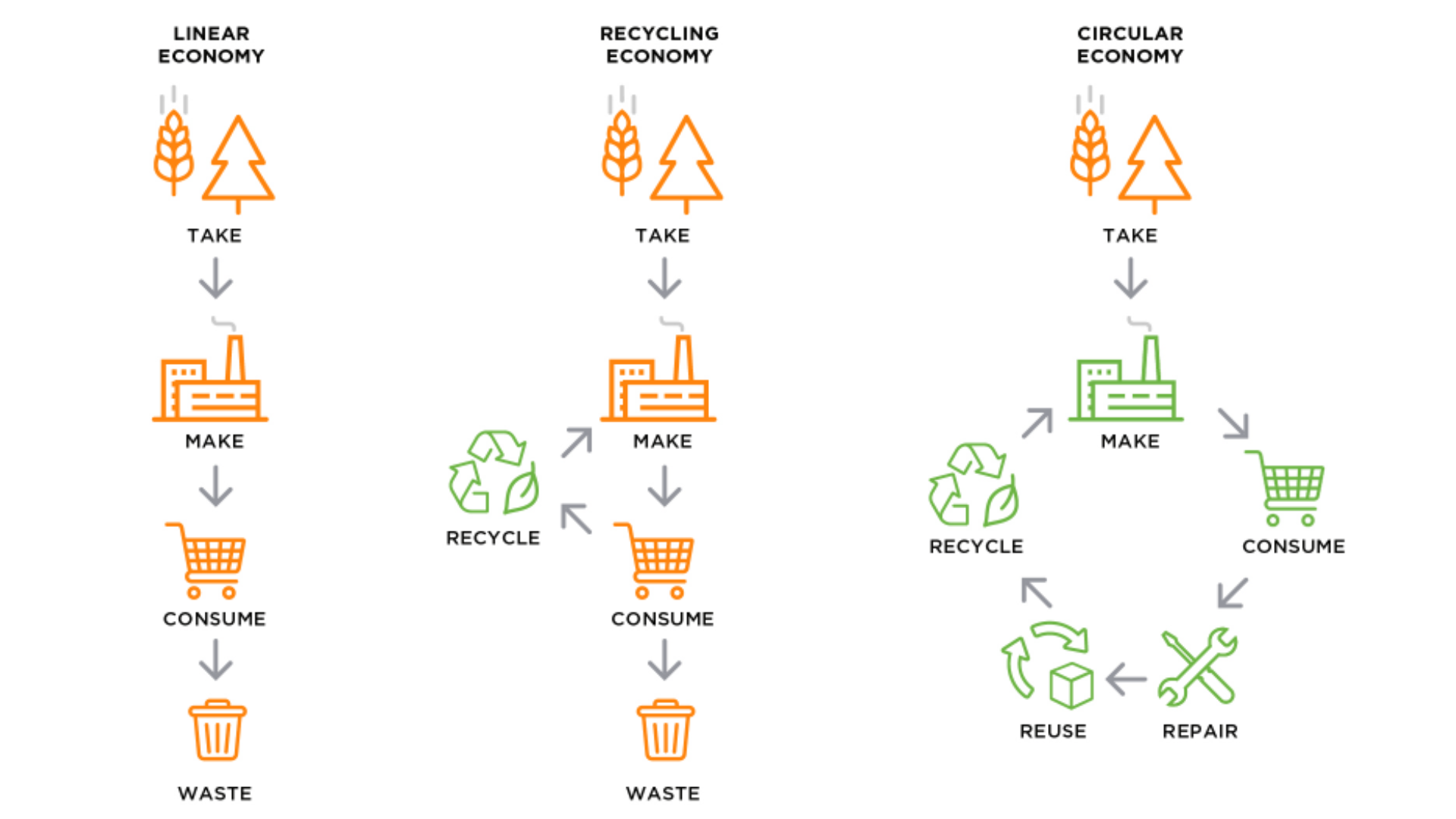

A circular economy is fundamentally regenerative, designed to gradually disengage growth from the depletion of finite resources1. It encompasses various aspects such as waste management, material utilization, and supply chain optimization. Among these, packaging plays a crucial role in realizing the vision of a truly circular economy2. Recognized as a fundamental cornerstone in transitioning from a linear to a circular system, packaging design is key to facilitating this shift smoothly.

Design plays a pivotal role within the packaging value chain3. A circular packaging design consists of material selection, design strategies that eliminate waste in logistical flows, packaging lifespan, and the reuse of virgin material, while still ensuring the full functionality of packaging and stellar protection of the product. It is estimated that as much as 80% of environmental impacts can be attributed to decisions made during the design phase, highlighting the significance of integrating circular principles into packaging design practices4. Read further as we investigate three main aspects of packaging design and engineering that ensure its positive impact on the environment.

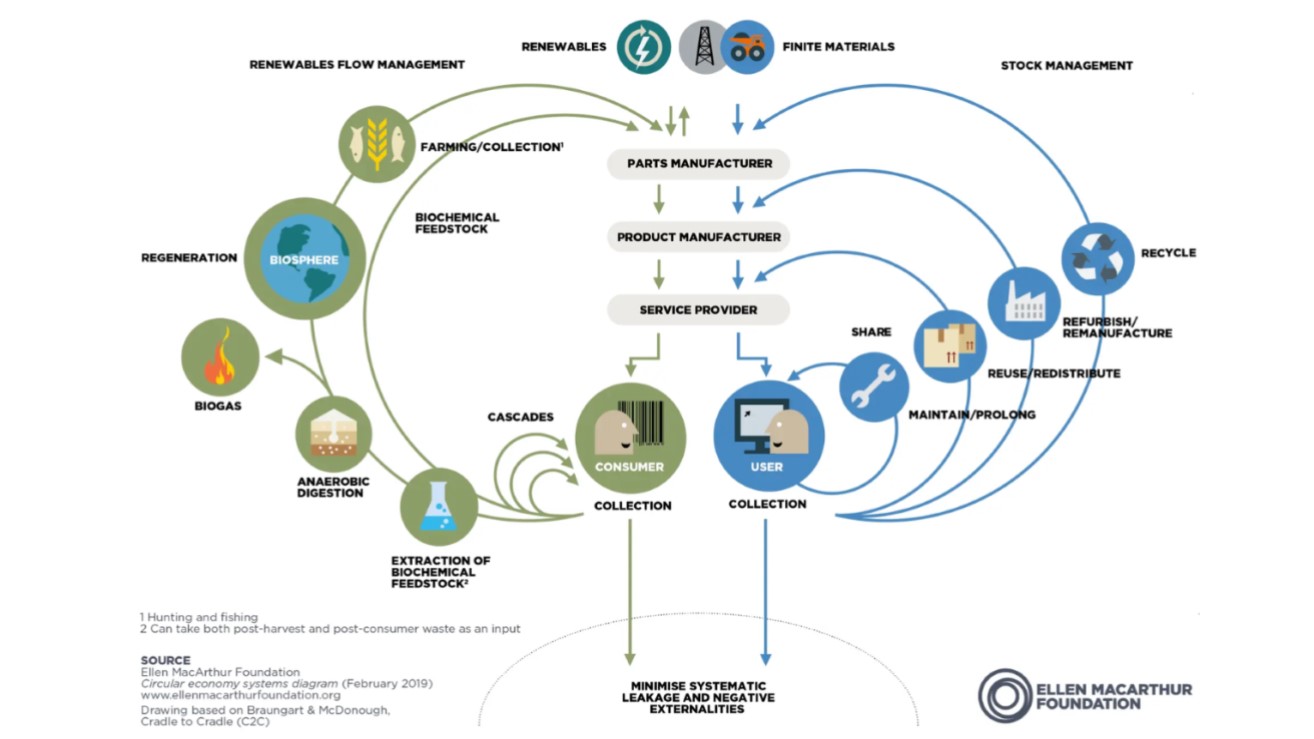

According to the Ellen MacArthur Foundation5, there are two primary cycles within the circular economy system: the technical cycle and the biological cycle. Within the technical cycle, products and materials are maintained in circulation via practices like reuse, repair, remanufacture, and recycling. On the other hand, the biological cycle involves the return of nutrients from biodegradable materials to the Earth, contributing to the regeneration of nature. Source: Ellen MacArthur Foundation

Sustainable Packaging Materials in Design

The packaging industry has traditionally operated within a linear model where packaging is conceived, manufactured, utilized, and eventually discarded. This was mostly due to the characteristics of packaging materials and their intended use. This approach generates significant waste, posing an increasingly pressing concern for the Earth's ecosystem. Traditional packaging predominantly comprises synthetic materials, which degrade over hundreds of years, releasing harmful substances into water and soil upon breakdown. Furthermore, these materials pose a threat to terrestrial and marine life, as they can inadvertently be ingested, leading to choking hazards for animals on land and in the sea6.

The packaging industry is constantly evolving, and new innovations in sustainable packaging are emerging. Sustainable packaging materials and sourcing are the foundation of circular solutions. Eco-friendly packaging materials are made from biodegradable or compostable materials and decompose naturally, reducing the negative impact on the environment. Choosing materials that have a higher recyclability rate can minimize waste. For example, packaging made from 100% recycled paper is recyclable in the paper streamwhich is the world's largest recycling stream.

According to a PMMI survey, most business leaders ranked adopting more recyclable packaging materials as their top priority. Source: PMMI

Designing Out Waste Through Packaging Design

Unfortunately, the packaging industry generates a lot of waste. According to the United Nations Environmental Programme (UNEP), every year across the globe more than two billion tonnes of municipal solid waste (MSW) are generated, which is enough waste to wrap around the Earth’s equator 25 times 7. That is why it is crucial to look for alternative solutions to reduce the numbers and alleviate MSW management. Sustainable packaging design is one of them.

When a product or packaging item consists of multiple materials that cannot be separated, it remains integral to the linear economy and ultimately ends up being discarded. In regions with comprehensive waste management services, this entails disposal either in a sanitary landfill or a waste-to-energy facility. Conversely, in areas lacking proper waste management infrastructure, these items are often incinerated openly, dumped in landfills, or left to contaminate the environment 8.

This is why effective waste management, akin to resource management, is imperative. One approach to achieve this is through the promotion of packaging design strategies that enhance the value of waste. It is crucial to meticulously consider every component of packaging to ensure that all materials utilized are either fully biodegradable or easily and economically recyclable. If a packaging material is recyclable but incurs significant costs, its inclusion may not be justifiable. For example, if two recyclable materials (like foam and corrugated) are glued together, they will be incinerated because their separation would be too expensive. Furthermore, waste management is intricately tied to local circumstances, with recycling regulations and capabilities varying from one region to another. Therefore, a comprehensive understanding of the local waste streams is essential to ensure that packaging is fully recyclable. This underscores the significance of tailored, customized solutions to address specific needs and requirements.

According to UNEP, every year across the globe more than two billion tonnes of municipal solid waste is generated that could wrap around the Earth’s equator 25 times. That is why sustainable packaging design is so crucial. Source: UNEP

Circular Business Models Closing the Loop

To create truly circular ecosystems, it is imperative to establish a network with partners throughout the value chain to offer sustainable business models. Cooperation can take many shapes, from take-back systems to returnable solutions for closed loop flows, for example. Take-back systems are gaining rapidly in popularity as solutions driven by the producers who collect the packaging at the end of its life and use it for creating something new (i.e. turning wooden chips into pallets). Thus, reducing the need for virgin materials across the value chain.

Returnable packaging also holds significant potential in the circular evolution. Overall costs and environmental implications must be considered when choosing returnable packaging, which can be especially advantageous for short-distance, frequent shipments targeting selected destination points. By investing in sturdy pallets, containers and racks, businesses conserve materials in packaging manufacturing and minimize waste generation, as well as enhance waste management practices.

Recognized as a fundamental cornerstone in transitioning from a linear to a circular system, packaging design is key to facilitating more effective waste management. Source: Nefab

The Transformation Starts with Commitment

Contemporary businesses are faced with the choice between linear and circular economies, uncertain about the best path forward for a smooth transition. Partnering with the right supplier can simplify the process of integrating circular principles into packaging design practices.

Nefab has introduced a set of guidelines for its engineers and designers that are core to our design process of innovative, sustainable packaging. The document focuses on key principles, including reducing the material used in packaging, fostering solutions related to its reusability, increasing the recycled content, and focusing on circular design. Along with the team training and GreenCalc LCA software, we continue to drive sustainability in our packaging and reduce our carbon emissions for the benefit of our customers and the environment.

We save resources in supply chains for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our smart and sustainable solutions.

LEARN MORE

GreenCalc

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Sustainable Solutions

Engineered packaging for sustainable supply chains

Sustainable Materials

Fiber-based packaging and raw materials