As the E-mobility industry surges forward, driven by the rising demand for electric vehicles (EVs), the sustainability of its supply chain is becoming a critical focus. The expanding battery market, while essential to this growth, faces significant challenges—not just in battery replacement but also in addressing the environmental impact of battery production. The extraction of minerals vital for lithium-ion batteries (LiBs) highlights the urgent need for sustainable practices, leading to the rise of a recycling industry that views EV batteries as valuable assets for sustainable reuse.

In response to these challenges, the industry is increasingly adopting circular solutions, particularly in battery recycling. A recent report1 from Stanford University, still under peer review, suggests that recycling LiBs can cut energy use by 79% and CO2 emissions by 55% compared to traditional refining methods. Furthermore, localizing recycling efforts enhances sustainability by minimizing the carbon footprint associated with global logistics. By embracing a closed-loop approach that integrates circular battery and packaging systems, the industry could significantly reduce total CO2-eq emissions. This shift underscores the need to redesign the entire value chain comprehensively. But how can packaging and logistics services support this vital transition?

Closed-Loop Systems: A New Standard in Sustainability

Reusable pooling solutions are integral to closed-loop systems in the E-mobility supply chain, offering a sustainable alternative to one-way packaging. These systems allow packaging to be cycled multiple times, with centralized management overseeing the storage, maintenance, and redistribution of materials. Pooling services provide flexibility in adjusting the size of the returnable packaging pool to your needs, whether you rent or own your packaging. After use, packaging is returned to a facility for inspection, cleaning, and repair, ensuring it is ready for the next cycle. Tracking and data-collection capabilities within these services enable companies to monitor logistical flows, optimizing efficiency and reducing waste. This approach minimizes the need for constant production, cuts down on storage and disposal burdens, and enhances overall sustainability in the supply chain.

Returnable solutions are critical in closed-loop systems, as they keep resources in circulation. By utilizing certified packaging, companies can ensure complete protection of battery cells and modules during transportation, all while maintaining the integrity of the supply chain. This holds true especially in the after-sales process for battery replacement when handling damaged or defective batteries. When a battery needs replacing, a spare is shipped to a service workshop using the packaging. After the old battery is removed, it is temporarily placed on the box lid while the new battery is installed. The old battery is then securely placed back into the packaging, which is reused to ship the spent battery out for proper disposal or recycling. This process not only ensures the safe handling of hazardous materials but also optimizes packing time, making the operations efficient and cost-effective.

Returnable and reusable packaging solutions offer a sustainable, cost-effective alternative to one-way packaging, reducing material use and simplifying end-of-life recycling.

Circularity in Practice: Thermoformed Trays

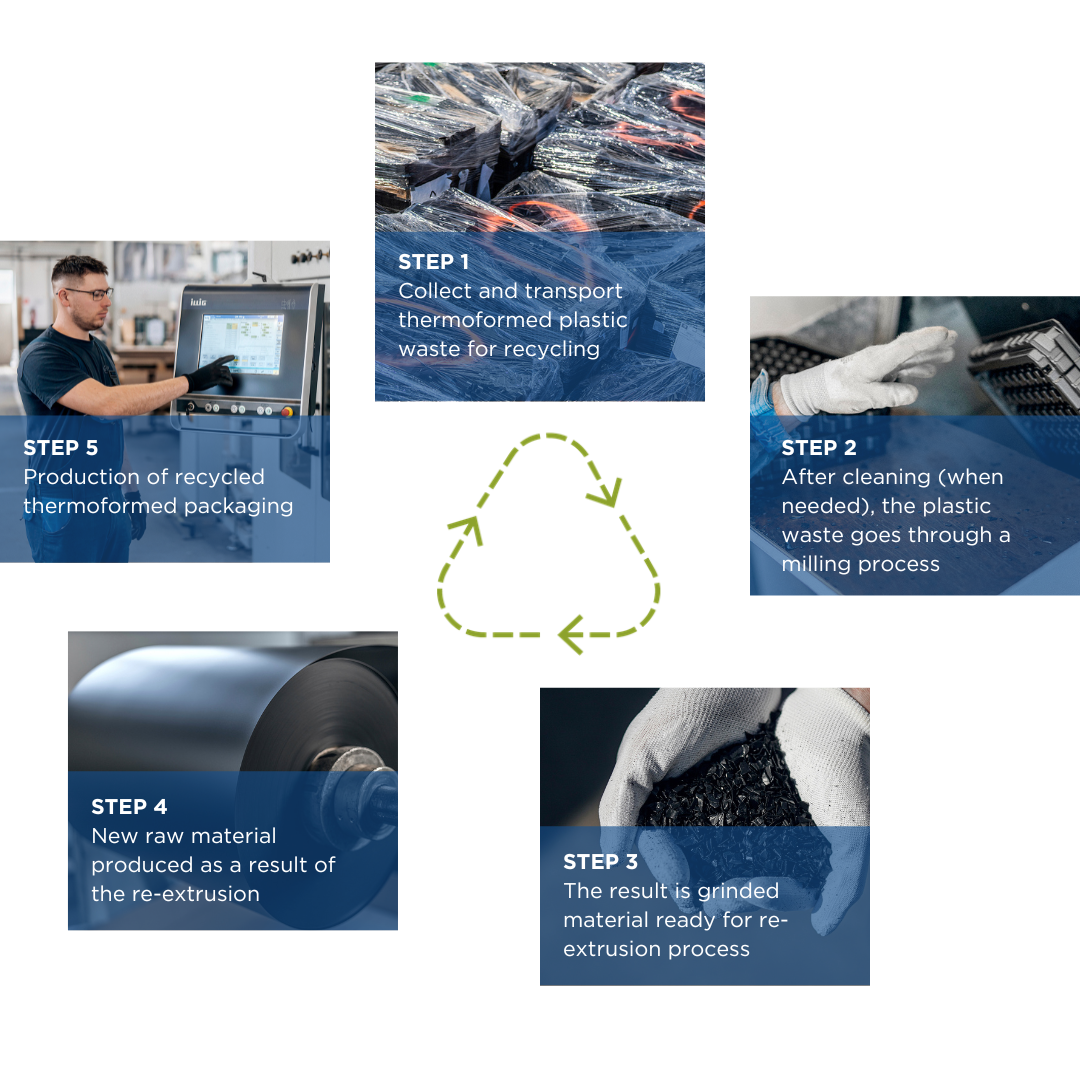

A good example of circularity in action is the use of circular thermoformed trays. These trays are designed with recycled materials and, at the end of their life cycle, can be collected, cleaned, and extruded to produce new trays. This closed-loop process keeps plastic trays in continuous use, contributing to a significant reduction in CO2-eq emissions and lowering the total cost within the supply chain. By embracing such circular solutions, companies can achieve both environmental and economic benefits, driving sustainability across the E-mobility value chain.

Nefab’s thermoformed solutions are designed with reduced materials and apply to circular flows. Once their life cycle ends, we collect our customers' thermoformed waste when possible, then clean, extrude, and reuse it as raw material to produce recycled thermoformed products.

Looking Ahead: A New Standard for Recycling Flows

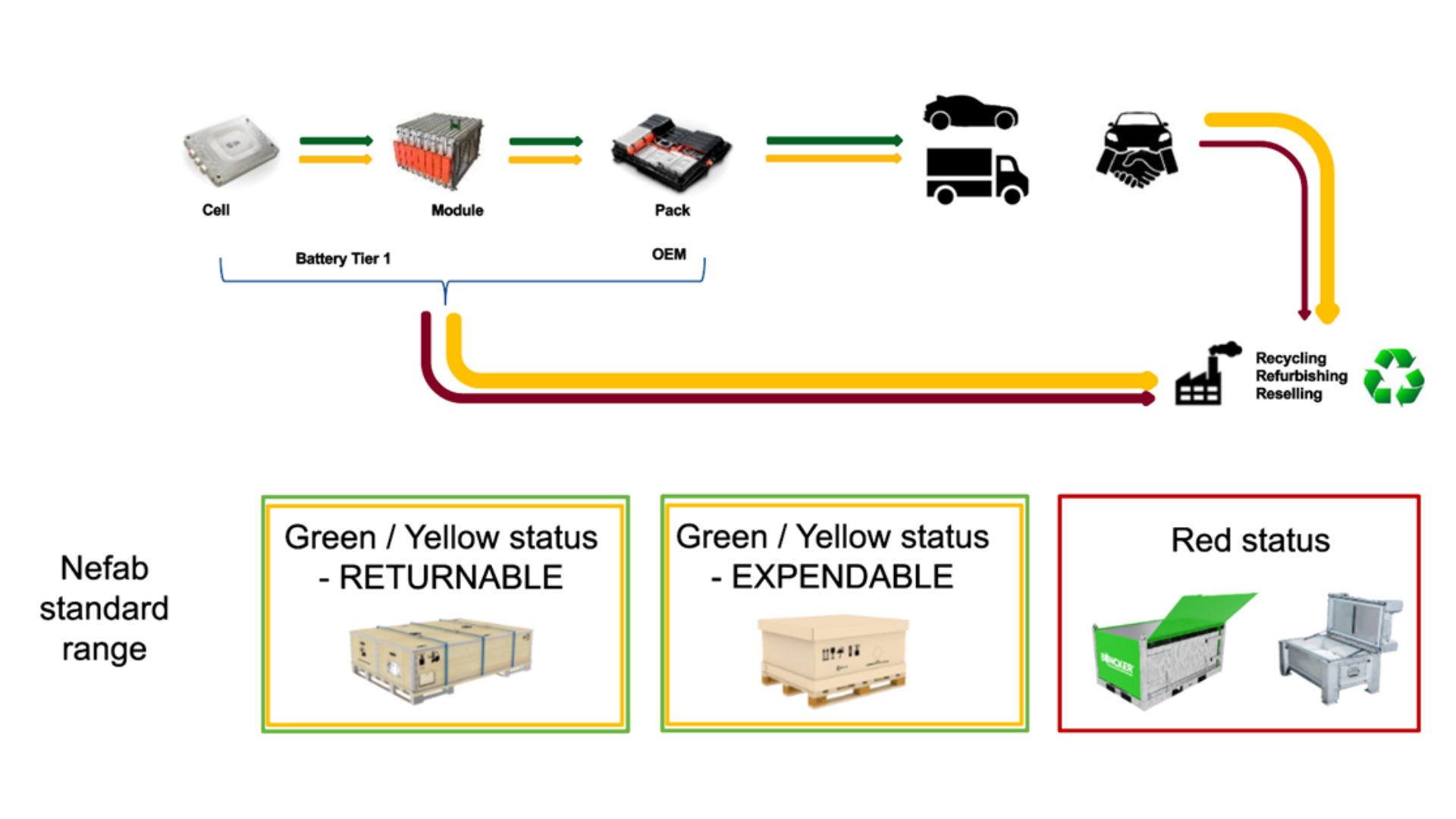

Nefab’s commitment to circular solutions is set to take another leap forward with the launch of a new standard packaging range for recycling flows. The range is fully UN-compliant, user-friendly, and compatible with different handling equipment. It covers all Li-battery statuses—green, yellow, and red status. It is designed to match various supply-chain requirements, from expendable to full returnable needs, and is readily available in stock.

In conclusion, the E-mobility industry is at a critical juncture where sustainability must be integrated into every aspect of the value chain. From battery recycling to circular packaging systems, embracing circular solutions is not just an option—it’s necessary to drive lasting change in the industry. As these practices continue to evolve, they will play a pivotal role in shaping a more sustainable future for the E-mobility sector.