- Novinky a postřehy

- 2024

- Jak překonat logistické problémy při dodávkách a instalacích zdravotnického vybavení

- Zdravotnické vybavení

- Odvětví

Jak překonat logistické problémy při dodávkách a instalacích zdravotnického vybavení

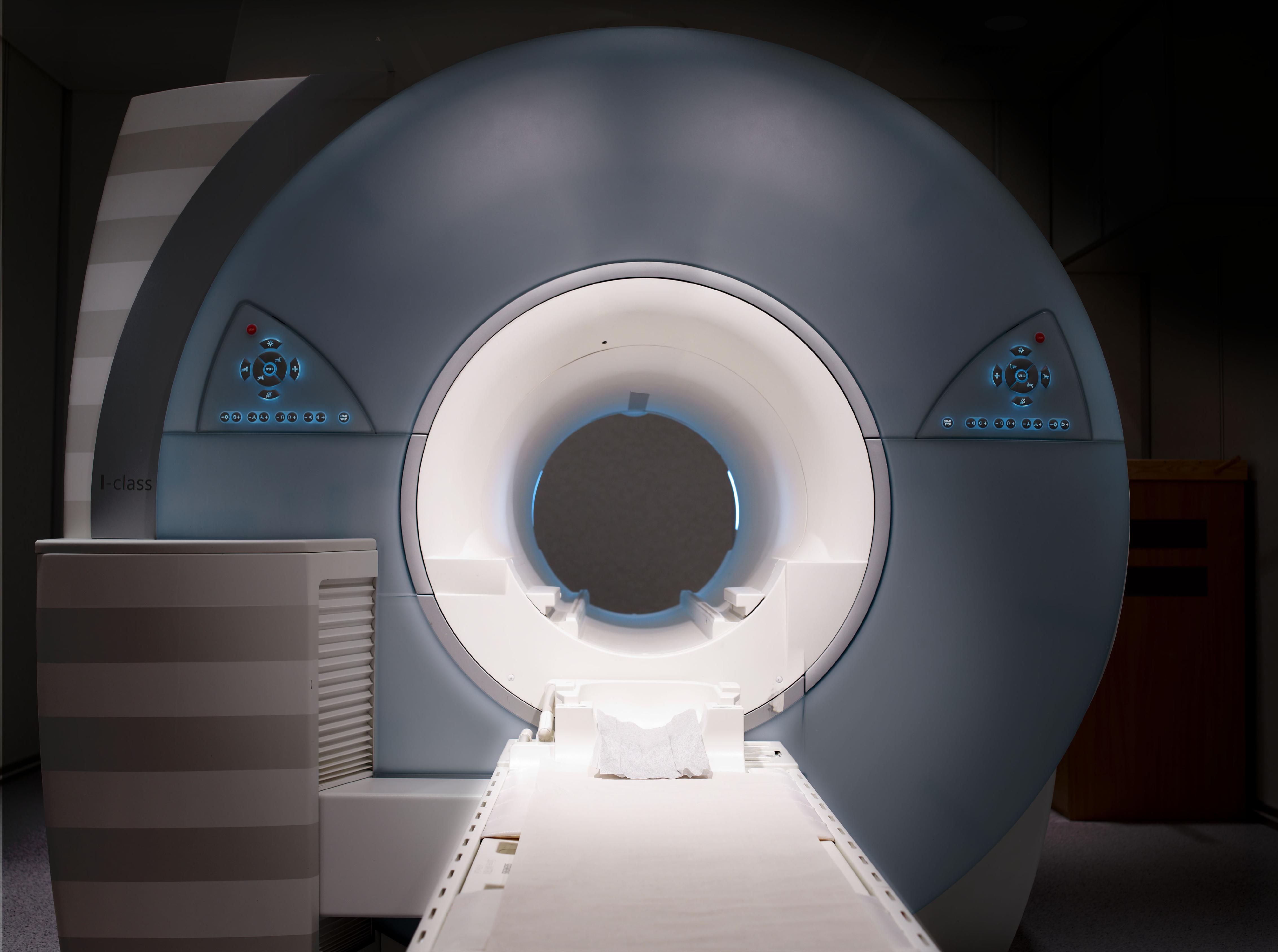

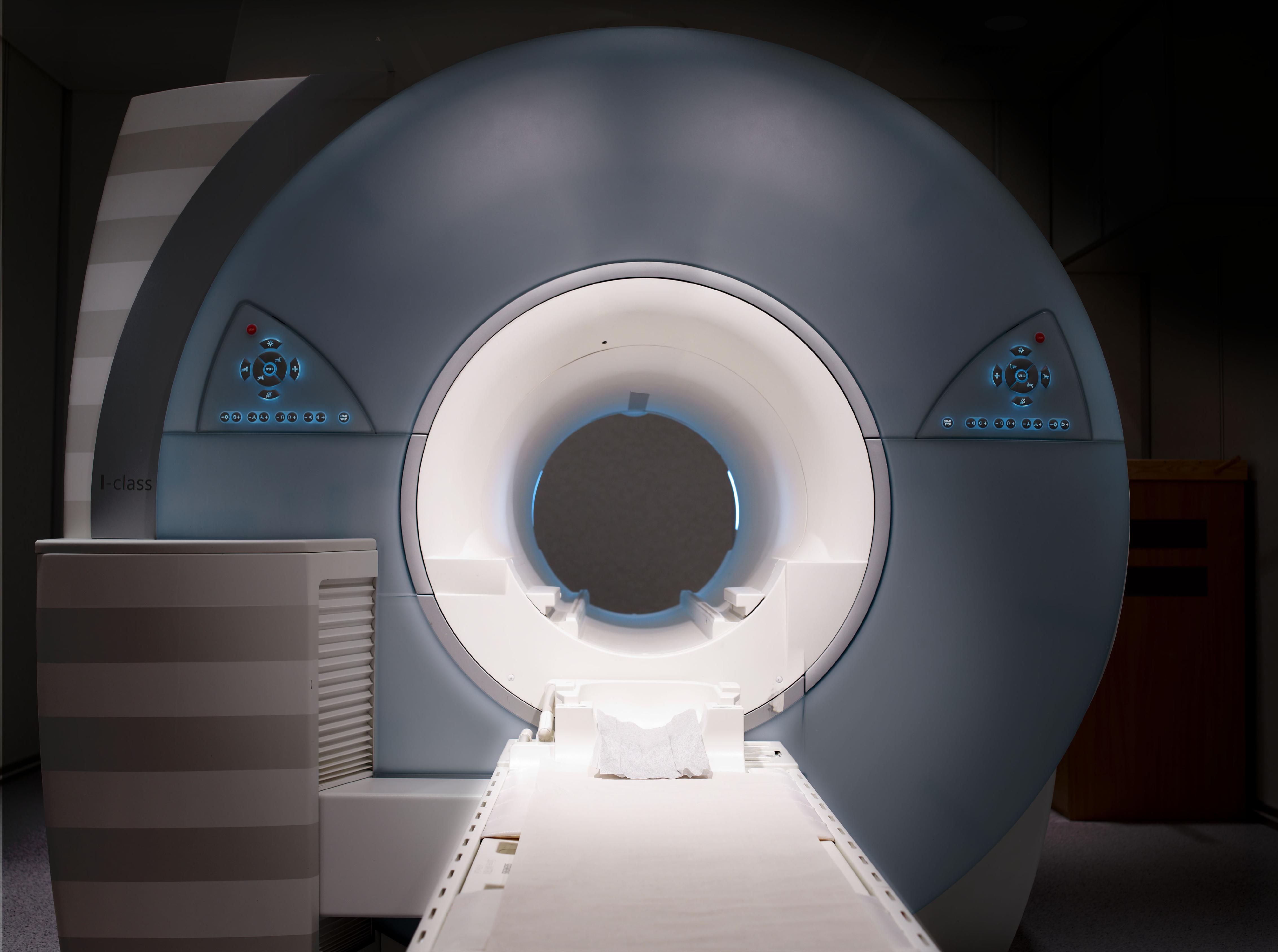

Manipulace s těžkým, objemným a drahým lékařským vybavením, jako jsou skenery MRI, CT a PET, vyžaduje pečlivé plánování a koordinaci.

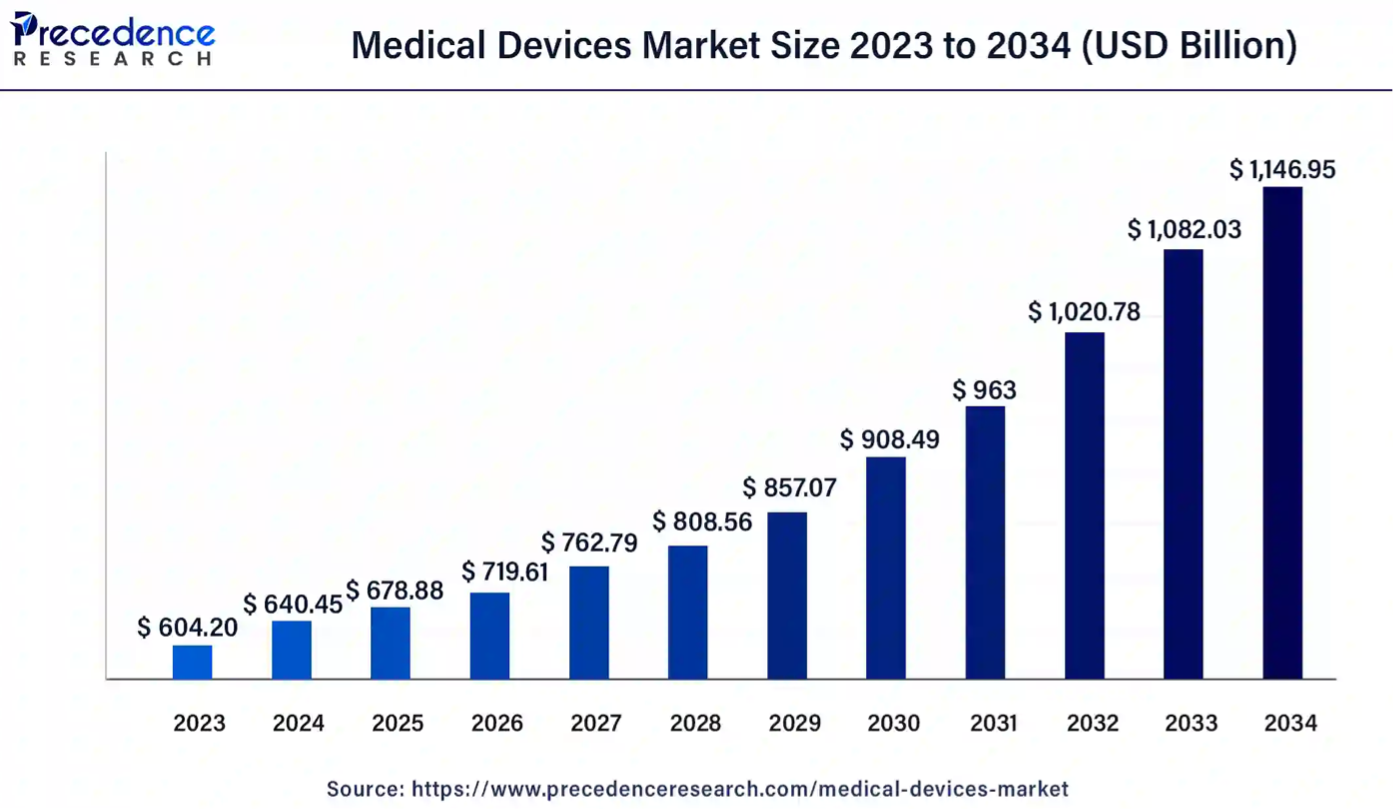

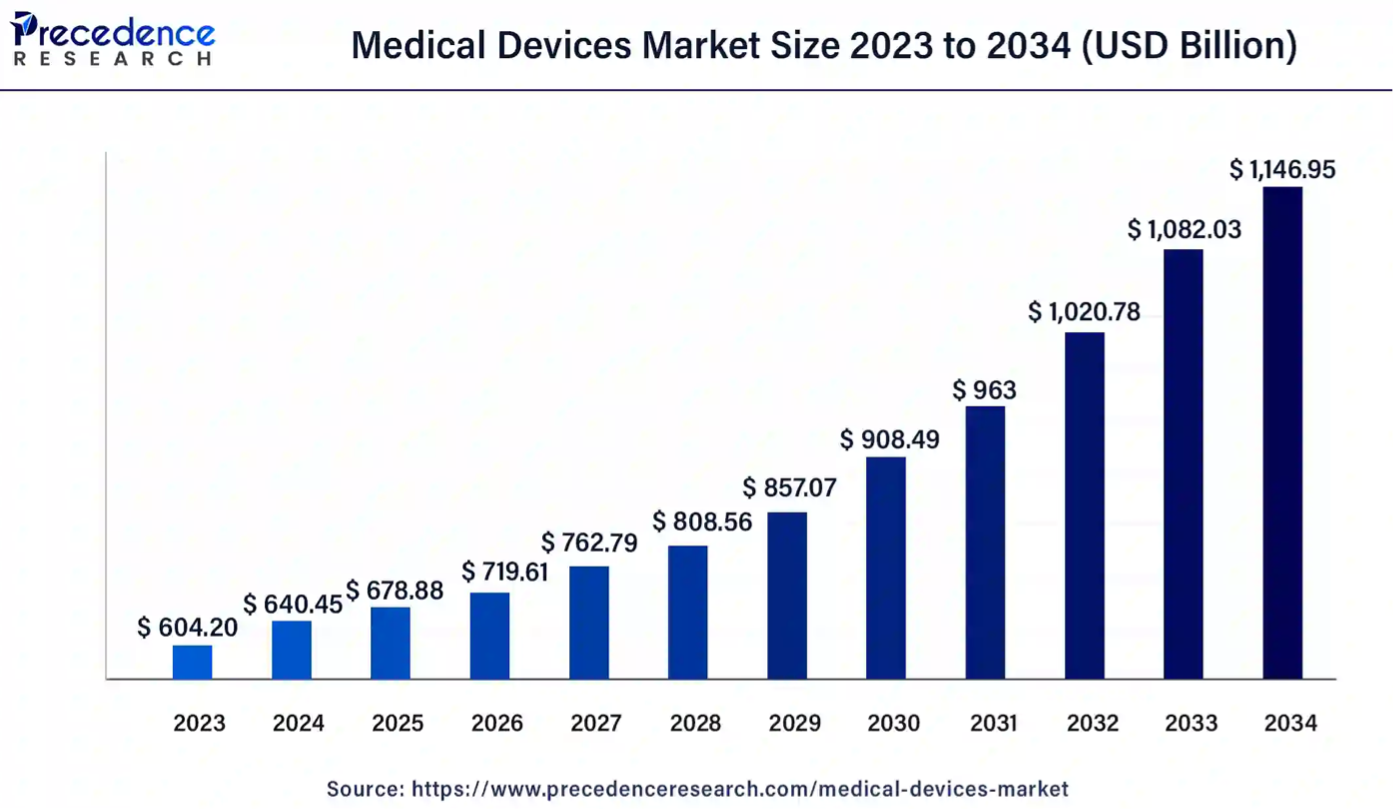

Trh se zdravotnickými prostředky je na vzestupu, což je dáno rostoucí poptávkou po špičkových zdravotnických řešeních. S rostoucím výskytem chronických onemocnění roste i potřeba inovativních přístrojů pro zlepšení péče o pacienty. Avšak zatímco vytváření takových zařízení je nepochybně složité, zajištění jejich bezpečného a včasného dodání představuje ještě větší výzvu - zejména v případě velkých a křehkých zařízení.

Očekává se, že rostoucí investice společností působících v oblasti zdravotnických technologií do výzkumu a vývoje spolu s racionalizací schvalování moderních přístrojů ze strany regulačních orgánů budou v nadcházejících letech hnací silou růstu trhu se zdravotnickými přístroji. Zdroj: Zdroj: Precedence Research

Problémy s přepravou těžkého zdravotnického vybavení

Manipulace s těžkým, objemným a drahým lékařským vybavením, jako jsou skenery MRI, CT a PET, vyžaduje pečlivé plánování a koordinaci. Tyto přístroje, které mohou vážit až 17 tun. 1, představují vzhledem ke své velikosti a citlivosti na vibrace, otřesy a vnější prostředí značné logistické problémy. Například přesun přístroje MRI je velmi složitý úkol, který vyžaduje ochranné obaly navržené tak, aby odolaly přepravnímu namáhání a zároveň zajistily bezpečnost a funkčnost přístroje. Přístroje MRI jsou nákladné a jejich ceny se liší v závislosti na faktorech, jako je síla magnetu, značka a model.2 Podle časopisu Money Magazine se celkové náklady na nákup a instalaci přístroje MRI pohybují od 3 do 5 milionů dolarů. 3. K tomu přistupuje fakt, že magnetická rezonance je závislá na kapalném héliu, které udržuje superchladnou teplotu, a jakékoli narušení může způsobit "zhasnutí", čímž se přístroj stane nefunkčním.4. Proto musí být magnetická rezonance přepravována v prostředí s kontrolovanou teplotou.

Řešení zpoždění instalace

Zpoždění instalace z důvodu chybějících nebo poškozených dílů je v každém odvětví běžné a týká se 20-40 % projektů.5. Ve zdravotnictví mohou mít taková zpoždění vážné důsledky a mohou narušit život zachraňující vyšetření a léčbu. Instalace lékařských zobrazovacích přístrojů je náchylná vzhledem ke složitosti zařízení a kritické roli, kterou hraje v diagnostice. Chybějící součástka nebo porucha během instalace by mohla zpozdit péči o pacienta, což by vedlo k prodloužení čekací doby nebo dokonce k odložení zákroků. Správné plánování a provedení jsou rozhodující pro zabránění škodám a zajištění úspěšné instalace. Specializovaná řešení pro správu instalace naštěstí mohou pomoci tato rizika minimalizovat a zajistit, aby byly přístroje pro zobrazovací zařízení dodány a nainstalovány včas a bez problémů.

Lékařské zobrazovací zařízení má zásadní význam pro přesnou diagnózu onemocnění, ale pokud není logistický proces efektivně řízen, může být drahé a jeho instalace se může zpozdit.

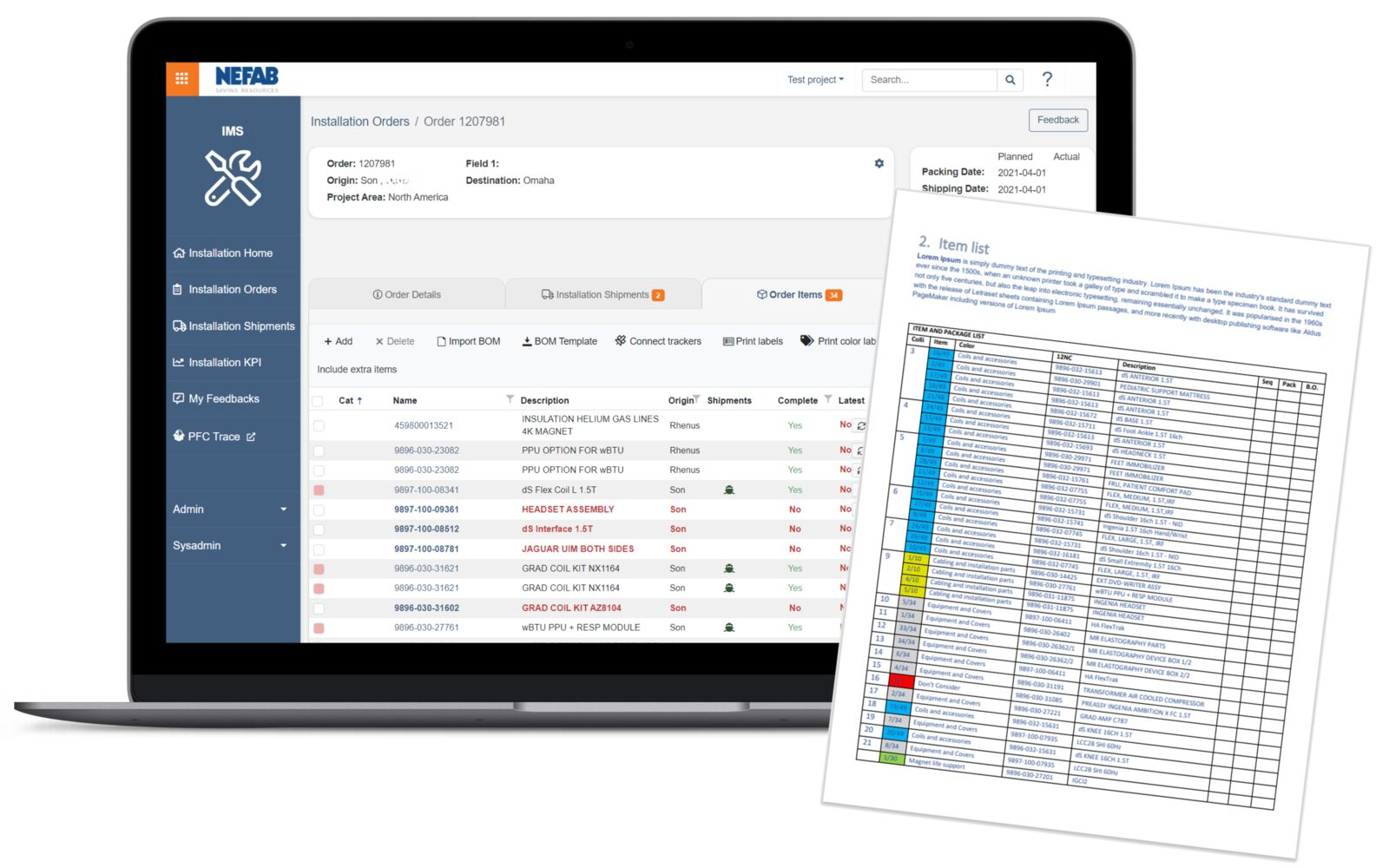

Co jsou služby správy instalací (IMS)?

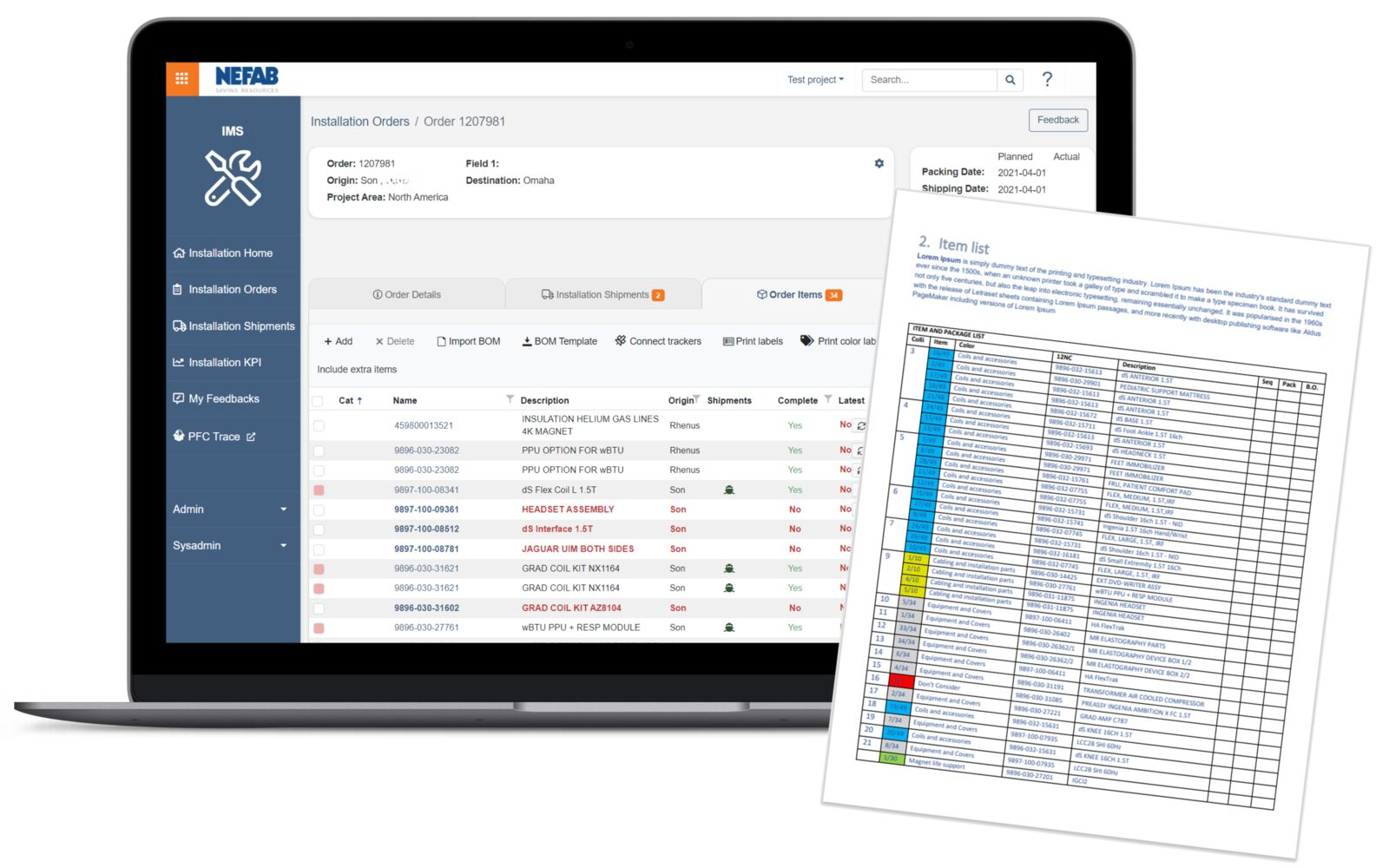

Řešení společnosti Nefab pro správu instalací (IMS) představuje flexibilnější alternativu k programům optimalizace poslední míle a nabízí možnosti přizpůsobené konkrétním potřebám a rozpočtům. Systém IMS, který je ideální pro komplexní instalace zahrnující více beden s příslušenstvím, složité dodavatelské řetězce a zásilky z různých zemí, zajišťuje hladší provoz díky pokročilému logistickému plánování, sledování v reálném čase a proaktivní koordinaci. Tento přístup řeší kritické detaily, jako je sledování komponent citlivých na teplotu, například helia, a minimalizace rizik, například poškození zařízení během přepravy. Zefektivněním celého procesu pomáhá systém IMS zajistit integritu zařízení a zároveň optimalizovat celkový časový plán instalace.

Dvoufázový přístup

Aby byla zajištěna maximální efektivita a přesnost složitého logistického procesu, zavedla společnost Nefab strategický dvoufázový přístup, který řeší jak plánování, tak realizaci v reálném čase.

- Fáze 1 se zaměřuje na pečlivé plánování, modelování a propojení, které zahrnuje vše od požadavků na balení až po pokyny k nakládání. Tato fáze se bezproblémově integruje s komplexní platformou pro sledování, která poskytuje přehled a koordinaci v celém dodavatelském řetězci.

- Fáze 2 začíná monitorováním v reálném čase a řízením zásilek, což umožňuje okamžité nápravné kroky, kdykoli je to nutné, aby se dodržel časový plán.

Tento dvoufázový přístup výrazně snižuje riziko chybějících nebo poškozených dílů, minimalizuje počet pracovních dnů na místě a zjednodušuje integraci zařízení od různých dodavatelů. Výsledek? Instalace "na první dobrou", které zvyšují provozní efektivitu a spokojenost zákazníků. Jak to vypadá v praxi? Hladký, zefektivněný proces, kdy jsou projekty dodávány včas, s menším počtem přerušení a větší přesností.

Platforma pro správu instalace umožňuje plánovat, sledovat a řídit proces instalace v reálném čase, zajistit, aby díly dorazily včas a nepoškozené, a zároveň identifikovat potenciální problémy dříve, než způsobí zpoždění.

Koordinované dodávky v praxi

Přední výrobce lékařských zobrazovacích zařízení se potýkal se značnými problémy při přepravě přístrojů MRI, které vyžadovaly zasílání více komponentů v samostatných krabicích na různých místech. Zásilky byly testovány na pěti místech po celém světě - v Německu, USA, Velké Británii, Číně a Japonsku -, přičemž každé z nich mělo své vlastní jedinečné překážky, od těžko přístupných oblastí až po velké sklady s různou úrovní přístupnosti a skladovacích podmínek. Špatná koordinace dodávek vedla k nákladným zpožděním, často způsobeným chybějícími, poškozenými nebo nesprávnými díly, zejména proto, že k instalaci zařízení byli najímáni instalatéři třetích stran. Pro řešení těchto problémů navázala společnost Nefab spolupráci s výrobcem, aby zefektivnila dodávky a instalace. Společnost zavedla ochranné přebaly, aby zabránila poškození, zavedla sledovací systémy pro rychlou identifikaci a řešení problémů a používala plánovací sady, aby minimalizovala chyby při balení a nakládání. Společnost Nefab také zavedla barevné kódování položek, aby urychlila a zjednodušila proces instalace. Tento dvouletý projekt nejenže společnosti ušetřil více než 900 tisíc eur (1 milion USD) ročně, ale také jí v roce 2020 vynesl prestižní ocenění "Supplier Excellence Award".

Optimalizace instalací zdravotnických zařízení

Složitost přepravy a instalace těžkého zdravotnického vybavení vyžaduje přesnost a koordinaci, kterou mohou zajistit pouze pokročilá logistická řešení. Společnost Nefab Installation Management Solution (IMS) řeší tyto problémy svým flexibilním dvoufázovým přístupem, který zajišťuje efektivní a včasnou instalaci a minimalizuje případná zpoždění nebo poškození zařízení. Díky řešením na míru, monitorování v reálném čase a lepšímu logistickému plánování zvyšuje systém IMS provozní efektivitu a přináší výrazné úspory nákladů, jak ukázal úspěšný pilotní program. S IMS mohou poskytovatelé zdravotní péče zajistit, že jejich kritické vybavení dorazí bezpečně a bude hladce nainstalováno, což zlepší péči o pacienty a jejich spokojenost.

Šetříme zdroje v dodavatelských řetězcích pro lepší zítřek.

Chcete se dozvědět více?

SPOJTE SE S NÁMI

Kontaktujte nás a dozvíte se více o našich chytrých a udržitelných řešeních.

ZJISTIT VÍCE

Řešení pro zdravotnictví

Optimalizujte svůj dodavatelský řetězec pomocí udržitelných řešení, která jsou v souladu s předpisy

GreenCalc

Vlastní certifikovaná kalkulačka společnosti Nefab měří a vyčísluje finanční a ekologické úspory našich řešení.