Tyto přístroje, které nabízejí bezkonkurenční přesnost a kontrolu, přinášejí revoluci do různých oborů, jako je všeobecná chirurgie, ortopedie a urologie. Očekává se, že celosvětový trh s chirurgickými roboty dosáhne do roku 2030 hodnoty 7,42 miliardy USD.1, je jejich vliv nepopiratelný.

S vývojem zdravotnické robotiky se však musí vyvíjet i obalová řešení, která ji chrání. Pokrok v oblasti chirurgických robotů, který je poháněn umělou inteligencí a zobrazovacími systémy, vyžaduje obaly, které poskytují vynikající ochranu a zároveň splňují standardy udržitelnosti a efektivity. Inovativní, na míru šitá obalová řešení jsou nezbytná pro zachování integrity zařízení, snížení emisí uhlíku a minimalizaci nákladů, což v konečném důsledku podporuje bezproblémovou integraci a zlepšuje péči o pacienty a provozní efektivitu.

Obaly, které chrání vysoce hodnotné technologie

Přeprava chirurgického robotického systému je vysoce rizikový proces. Při ceně jednoho systému přes 2 miliony USD2-a další náklady na školení a údržbu - je zajištění bezpečné přepravy těchto sofistikovaných strojů s vysokou hodnotou velmi důležité. Přeprava takového systému zahrnuje několik fází manipulace a způsobů přepravy, z nichž každá představuje vlastní soubor rizik. Vzhledem k těmto výzvám hraje balení zásadní roli při ochraně této významné investice. Zde jsou klíčové faktory, které je třeba mít na paměti při výběru obalu pro high-tech zařízení, jako jsou chirurgické roboty:

- Ochrana proti nárazům a vibracím: U chirurgických robotů je nezbytné tlumení vibrací, protože složité mechanismy a přesné součásti mohou být během přepravy poškozeny nárazy nebo vibracemi. Účinná řešení tlumení chrání citlivé součásti, zachovávají přesnost provozu robota a prodlužují jeho životnost, což je pro poskytovatele zdravotní péče, kteří na tyto systémy spoléhají při kritických zákrocích, zásadní.

- Klimatické stínění: Stejně důležitá je odolnost proti vlhkosti a tepelná ochrana. Chirurgické roboty obsahují citlivou elektroniku a senzory, které mohou být ohroženy vlhkostí nebo kolísáním teploty. Vlhkost může vést ke korozi nebo zkratu, zatímco změny teploty mohou ovlivnit funkčnost komponent citlivých na teplotu a ovlivnit přesnost robota. Díky použití materiálů a konstrukcí, které tato rizika zmírňují, pomáhají obalová řešení zachovat spolehlivost a bezpečnost chirurgických robotů v různých podmínkách prostředí.

- Udržitelnost a efektivita: Moderní obalová řešení se musí zaměřit také na optimalizaci prostoru. Efektivní využití prostoru nejen snižuje náklady na přepravu, ale také zajišťuje bezpečné uložení robotů a jejich choulostivých součástí, čímž se minimalizuje riziko poškození během přepravy. Klíč spočívá v přizpůsobení obalu jedinečným rozměrům a požadavkům každého systému, optimalizaci každého centimetru prostoru při zachování potřebné ochrany.

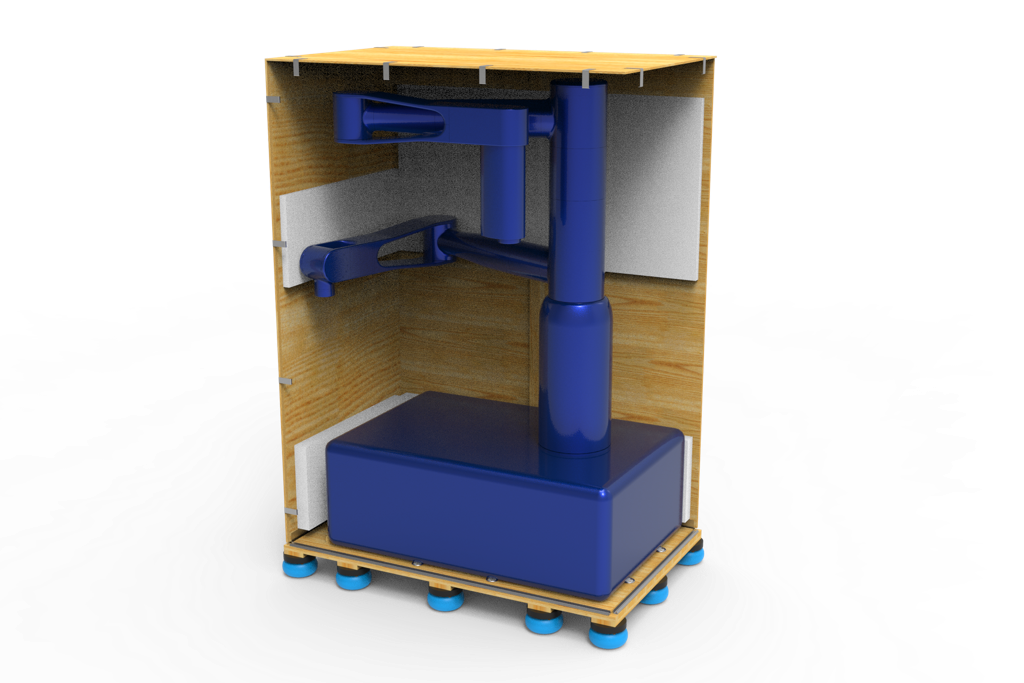

Autorství obrázku

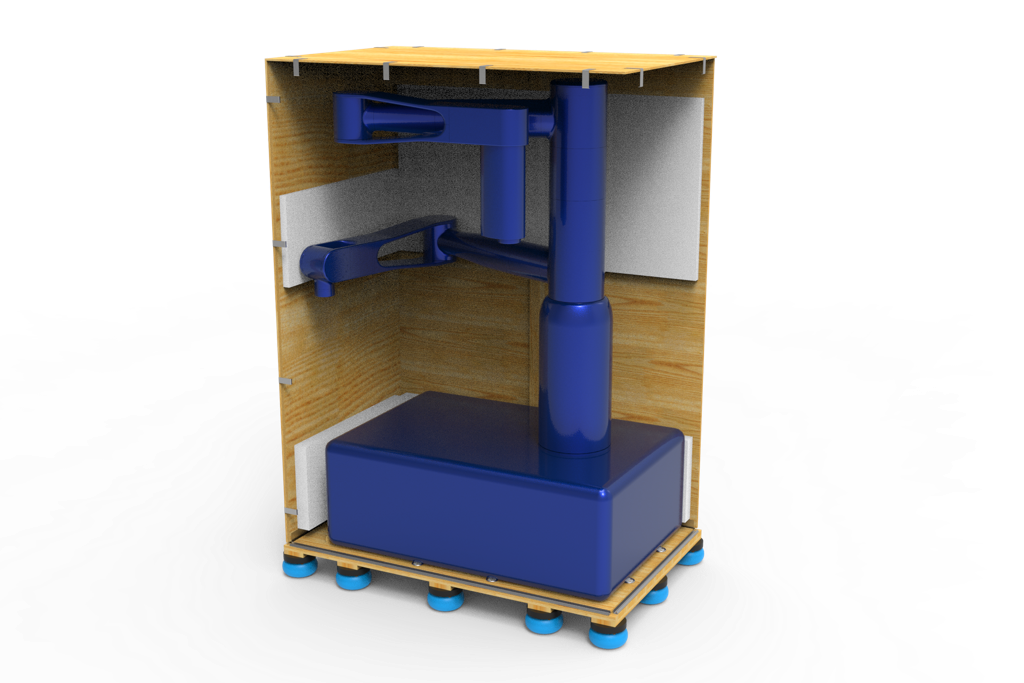

Autorství obrázku

Reálné výsledky v oblasti snižování nákladů a udržitelnosti

Obaly se mohou zdát jako maličkost, ale mohou být hybnou silou významných změn - jak pro podniky, tak pro planetu. Vezměte si případ předního výrobce minimálně invazivních chirurgických robotů. Závislost společnosti na tradičních dřevěných bednách s ocelovým kováním způsobovala poškození výrobků, logistickou neefektivitu a rostoucí náklady. Při hledání lepšího řešení společnost navázala spolupráci se společností Nefab jejíž inženýři využili své odborné znalosti k optimalizaci logistické cesty jednoho robota od začátku až do konce. Přechodem na lehké překližkové obaly systém, společnost snížila hmotnost o 60 kg na zásilku, zefektivnila manipulaci díky montáži bez hřebíků a zabezpečila své roboty pomocí vlastních tlumicích prvků. Stránky Výsledky byly převratné - o 29 % nižší emise CO2-a 25% roční úspora nákladů-což dokazuje, jak může obal na míru skutečně změnit situaci.

ExPak XL je lehký obal z překližky, který snižuje hmotnost, zvyšuje efektivitu manipulace a chrání vysoce hodnotné chirurgické roboty pomocí speciálních tlumicích prvků, což vede ke snížení emisí CO2-a významnou úsporu nákladů.

Partnerství pro budoucnost logistiky ve zdravotnictví

S tím, jak se chirurgická robotika stává složitější, jsou stále důležitější inovativní obalová řešení. Obaly na míru mohou nejen zefektivnit proces přepravy, ale také výrazně zlepšit udržitelnost. Podporou spolupráce a zaváděním inovací mohou společnosti řešit složité problémy tohoto rozvíjejícího se odvětví a zároveň dosáhnout výrazných úspor nákladů a snížení emisí.

Díky rozsáhlým zkušenostem v oblasti balení a inženýrských inovací ve zdravotnictví spolupracuje společnost Nefab s předními výrobci chirurgických robotů, aby se vypořádala s jedinečnými výzvami spojenými s přepravou těchto sofistikovaných systémů. Díky úpravám obalů pomáhá společnost Nefab výrobcům snížit celkové náklady a emise CO2 ekv. přibližně o 20-30 %. Řešení společnosti kombinují pokročilé materiály, inženýrské znalosti a hluboké porozumění potřebám zdravotnického průmyslu, čímž zajišťují produkt a zároveň optimalizují logistiku.Tím, že společnost Nefab upřednostňuje udržitelnost a integritu výrobků, podporuje výrobce v plnění jejich cílů v oblasti životního prostředí a v rozvoji péče o pacienty.

Šetříme zdroje v dodavatelských řetězcích pro lepší zítřek.

Chcete se dozvědět více?

SPOJTE SE S NÁMI

Kontaktujte nás a dozvíte se více o našich chytrých a udržitelných řešeních.

ZJISTIT VÍCE

Řešení pro zdravotnictví

Optimalizujte svůj dodavatelský řetězec pomocí udržitelných řešení, která jsou v souladu s předpisy

GreenCalc

Vlastní certifikovaná kalkulačka společnosti Nefab měří a vyčísluje finanční a ekologické úspory našich řešení.