- Novinky a postřehy

- 2025

- Klíčové obalové politiky a předpisy, které je třeba sledovat v roce 2025? Část 2/2

Klíčové obalové politiky a předpisy, které je třeba sledovat v roce 2025? Část 2/2

Ve druhé části se zaměříme na globální vývoj zákonů o rozšířené odpovědnosti výrobce (EPR). Tyto předpisy mění způsob, jakým společnosti nakládají s obalovým odpadem, a ukládají výrobcům větší odpovědnost za udržitelnost.

V první části tohoto seriálu jsme se zabývali nařízením Evropské unie o obalech a obalových odpadech (PPWR) a jeho důsledky pro podniky (přečíst si jej můžete zde). Nyní se ve druhé části zaměříme na celosvětový vývoj zákonů o rozšířené odpovědnosti výrobce (EPR). Tato nařízení mění způsob, jakým společnosti nakládají s obalovým odpadem, a ukládají výrobcům větší odpovědnost za prosazování udržitelnosti.

Systémy EPR přenášejí břemeno odpadů zpět na výrobce

EPR je přístup k nakládání s odpady, který ukládá výrobcům odpovědnost za dopad jejich výrobků, včetně obalů, na životní prostředí. Nedodržování politiky EPR může vést k pokutám, právním sankcím nebo omezení prodeje výrobků na určitých trzích. Cílem těchto opatření je zajistit, aby výrobci brali svou odpovědnost za životní prostředí vážně a přispívali k udržitelnému nakládání s odpady.1.

Evropa je v čele změn

EU a Spojené království v posledních letech dosáhly významného pokroku v prosazování politik EPR, zejména v oblasti obalů. Tyto změny aktualizují stávající pravidla pro obaly a další odpady a rozšiřují požadavky EPR tak, aby zahrnovaly více výrobců a výrobků. Přinášejí také nová pravidla pro dodržování předpisů a finanční odpovědnost.

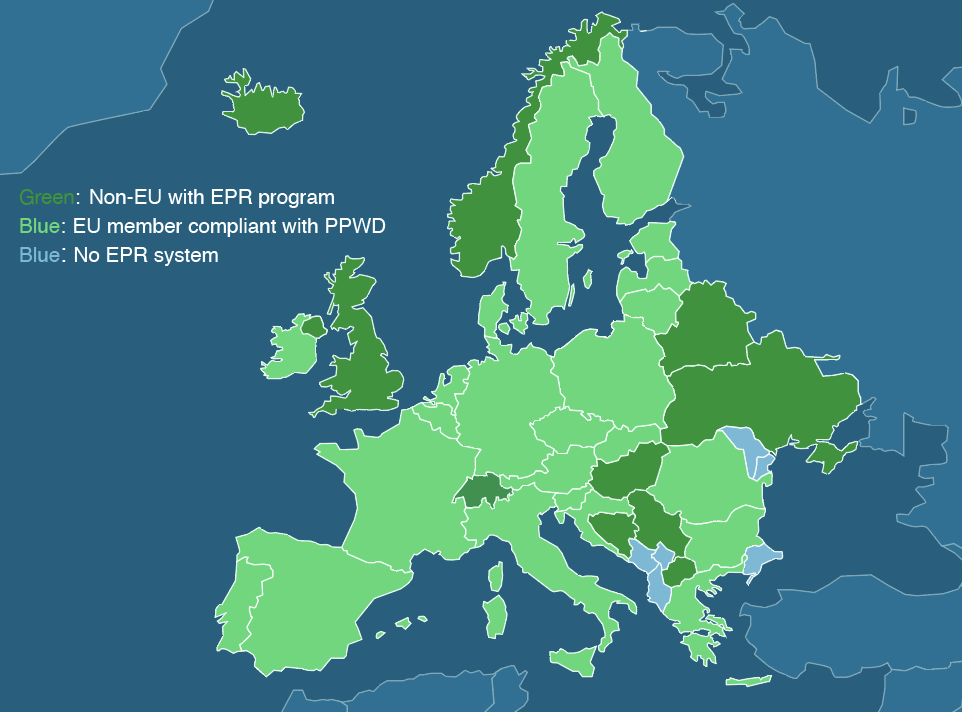

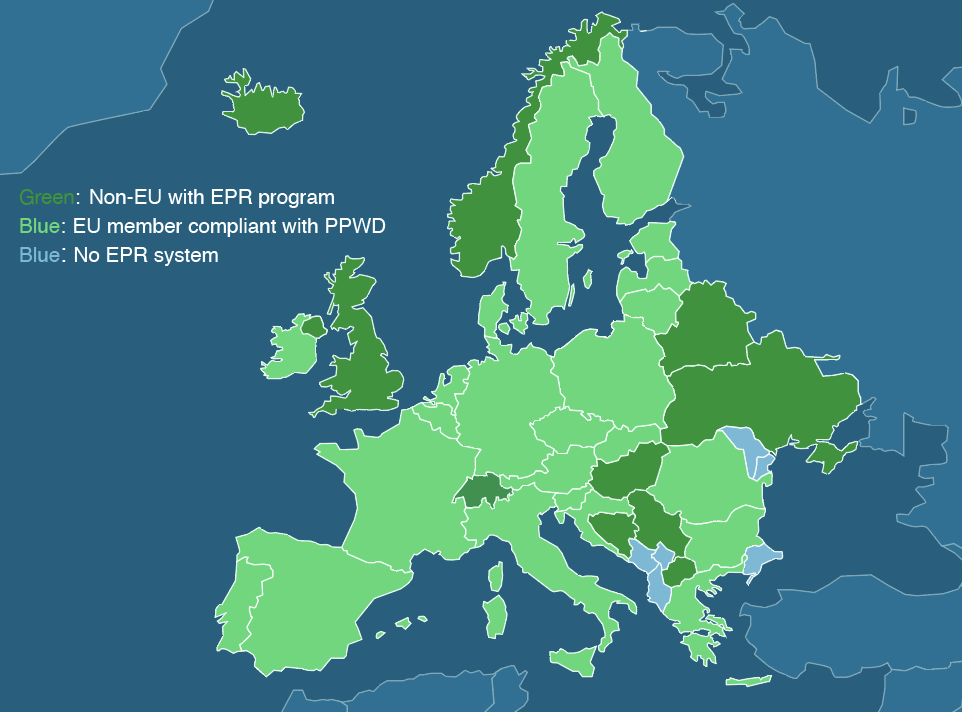

Cílem zásad EPR je harmonizovat environmentální politiky v členských státech EU, jejich provádění se však liší v závislosti na vnitrostátních podmínkách. Směrnice o obalech a obalových odpadech vyžaduje, aby všechny členské státy do roku 2024 zavedly systémy EPR pro obaly, přičemž se vyvažují jednotné cíle s místními úpravami.2. S rozšiřováním EPR se výrobci musí přizpůsobit významným změnám v nakládání s obaly.

Zdroj: Škola balení

S rozšiřováním systémů rozšířené odpovědnosti výrobce (EPR) se výrobci musí přizpůsobit významným změnám v nakládání s obaly.

Zákony o EPR v USA

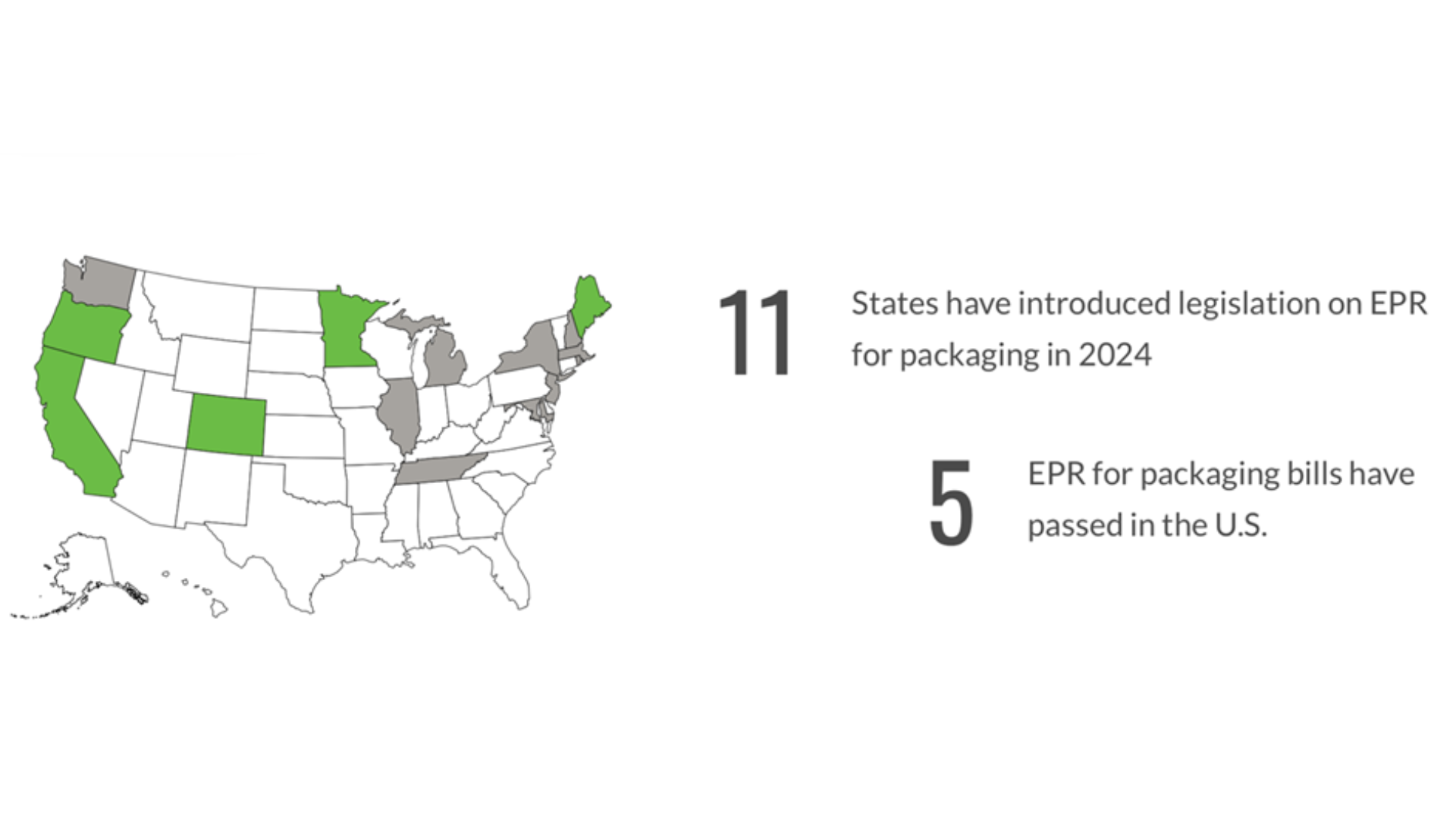

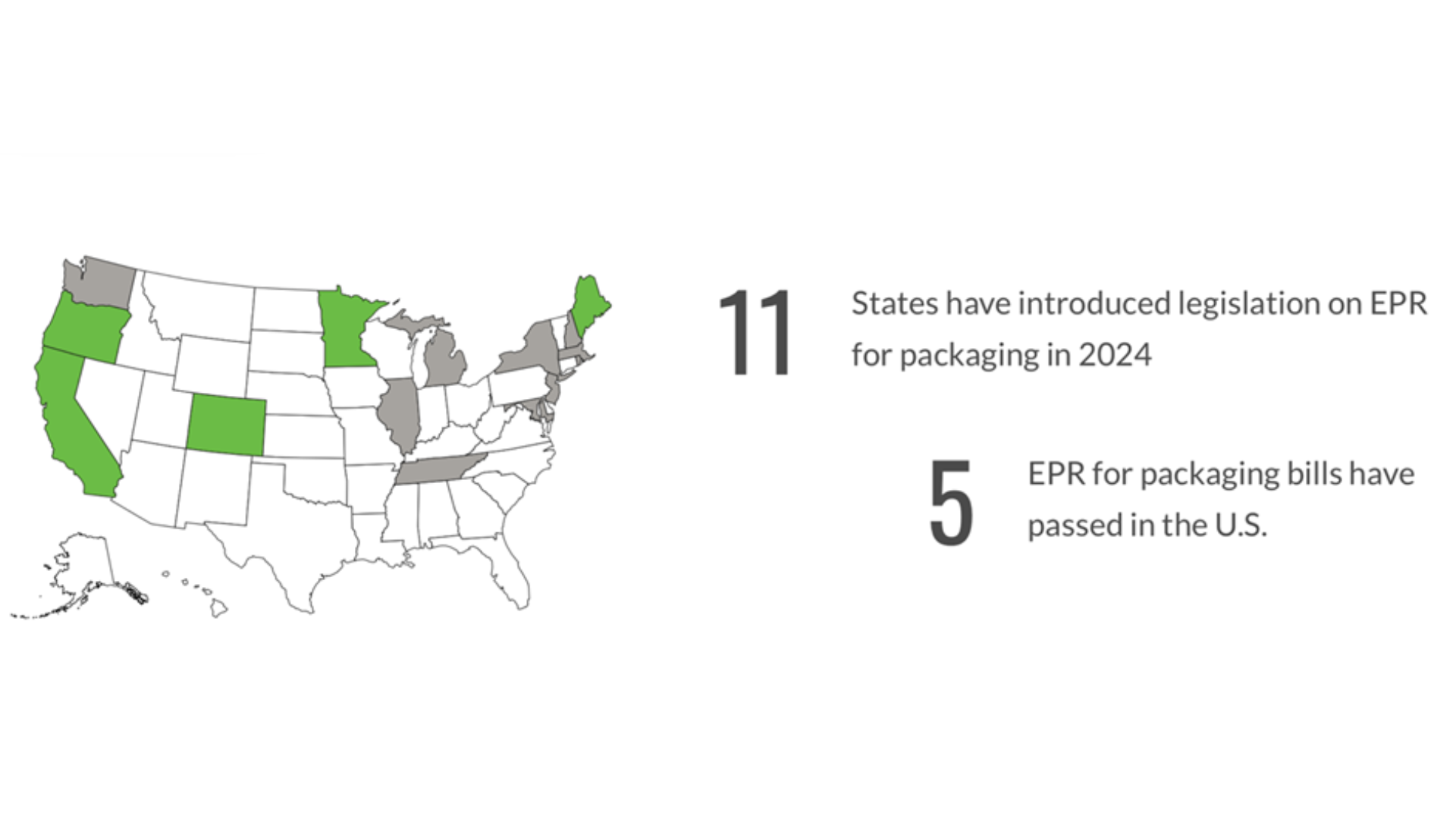

Od roku 2024 má pět amerických států aktivní zákony o EPR nebo podobné zákony o obalech: Kalifornie, Colorado, Maine, Oregon a Minnesota. Z nich se Oregon ujme vedení jako první stát, který bude od července 2025 prosazovat EPR, přičemž první zprávy o dodávkách mají být předloženy do 31. března 2025.3.

Kromě těchto států zvažuje podobnou legislativu nejméně devět dalších, což naznačuje, že v roce 2025 a v dalších letech se pravděpodobně objeví další pravidla pro balení.4.

Pro výrobce bude orientace v těchto předpisech složitá, a to i v pěti státech, kde již zákony platí. Přístupy jednotlivých států se výrazně liší, přičemž rozdíly jsou následující:

- Definice "výrobce".

- Kategorie materiálů, na které se vztahuje.

- Zvláštní výjimky.

- Harmonogramy provádění5.

EPA vyzývá k vytvoření národního rámce EPR

Americká agentura EPA doporučuje vytvořit národní rámec rozšířené odpovědnosti výrobce (EPR) jako součást národní strategie prevence znečištění plasty, jejímž cílem je eliminovat plastový odpad v životním prostředí do roku 2040. Ačkoli se v nejbližší době neočekává přijetí federálního zákona o EPR, dynamika se zvyšuje a EPA zdůrazňuje potřebu spolupráce a harmonizovaných politik, které čerpají z příkladů na úrovni jednotlivých států a na mezinárodní úrovni s cílem zvýšit míru recyklace, snížit množství odpadu a dosáhnout cílů oběhového hospodářství.

Vzhledem k tomu, že se regulační rámec stále rozšiřuje, musí výrobci zůstat pružní, aby se těmto různorodým a vyvíjejícím se požadavkům přizpůsobili.

Pět amerických států přijalo aktivní zákony o EPR nebo podobné zákony o obalech a nejméně 11 dalších o podobné legislativě uvažuje Zdroj: Koalice pro udržitelné obaly

APAC přechází na povinná opatření EPR

Země v celém indo-pacifickém regionu přecházejí od dobrovolných k povinným politikám rozšířené odpovědnosti výrobce (EPR), což odráží rostoucí závazek k udržitelnému nakládání s odpady. Tyto politiky vyžadují, aby společnosti vyrábějící plastové výrobky nesly náklady na jejich sběr, třídění a recyklaci.

Regionální vývoj

- Malajsie: Malajsie začlenila rozšířenou odpovědnost výrobce (EPR) do svého plánu udržitelnosti plastů (2012-2030) a plánu oběhového hospodářství pro tuhé odpady (2025-2035). Na nedávném kulatém stole s Norskem, OSN a dalšími zúčastněnými stranami byl kladen důraz na pokrok v zavádění EPR. Ačkoli je současný systém EPR v Malajsii dobrovolný, ministerstvo investic, obchodu a průmyslu (MITI) plánuje, že do roku 2026 bude povinný, což signalizuje silný závazek posílit EPR v blízké budoucnosti.

- Thajsko: Od roku 2025 Thajsko zakáže dovoz veškerého plastového odpadu v rámci své iniciativy proti znečištění plastem.6. V březnu 2024 představilo thajské ministerstvo přírodních zdrojů a životního prostředí návrh zákona o udržitelném nakládání s obaly, který položí základ pro zavedení rozšířené odpovědnosti výrobce (EPR) pro obaly. Byl stanoven tříletý časový rámec pro vytvoření potřebné infrastruktury EPR, včetně centralizované digitální platformy pro registraci výrobců.7.

- Austrálie: Austrálie zvažuje komplexní reformu svých předpisů o obalech, která zahrnuje následující možnosti:

-

- Posílení stávajících rámců.

- Zavedení povinných vnitrostátních norem.

- Zavedení režimu EPR.

Hlavní návrhy se zaměřují na zákaz problematických chemikálií, nařizují recyklovaný obsah a zlepšují normy recyklovatelnosti. Rozšířené konzultace s průmyslem se očekávají v průběhu roku 2025.8. Národní cíle v oblasti obalů navíc usilují o to, aby do roku 2025 bylo 100 % obalů opakovaně použitelných, recyklovatelných nebo kompostovatelných, přičemž se zaměřují na postupné odstraňování nepotřebných plastů na jedno použití.

Země v celém indo-pacifickém regionu přecházejí od dobrovolných k povinným politikám rozšířené odpovědnosti výrobce (EPR), což odráží rostoucí závazek k udržitelnému nakládání s odpady.

V regionu APAC dochází k významným regulačním změnám, které mají být v souladu s globálními cíli udržitelnosti. Vzhledem k tomu, že země mění své předpisy týkající se obalů a přijímají přísnější rámce EPR, musí se podniky připravit na budoucnost, kdy udržitelné obaly nebudou volitelné, ale povinné.

Kdo vám může pomoci při změnách?

Ve společnosti Nefab rozumíme výzvám, kterým podniky čelí v souvislosti s novými předpisy o obalech. Jako důvěryhodný partner s rozsáhlými odbornými znalostmi v oblasti udržitelnosti tyto změny pozorně sledujeme a jsme připraveni vás provést jejich dodržováním.

Společnost Nefab vám může pomoci přizpůsobit se vyvíjejícím se standardům a prosperovat v novém prostředí - od návrhu udržitelných obalů až po zavedení systémů opakovaného použití a posouzení životního cyklu.

Šetříme zdroje v dodavatelských řetězcích pro lepší zítřek.

Chcete se dozvědět více?

SPOJTE SE S NÁMI

Kontaktujte nás a dozvíte se více o našich chytrých a udržitelných řešeních.

ZJISTIT VÍCE

Udržitelná řešení

Obaly pro udržitelné dodavatelské řetězce

GreenCalc

Vlastní certifikovaná kalkulačka společnosti Nefab měří a vyčísluje finanční a ekologické úspory našich řešení.

Globální inženýrská síť

250 inženýrských odborníků na více než 30 místech