Protection to prevent corrosion

Products that are transported for a longer period of time or stored for an extended length are often in need of corrosion protection. Corrosion protection packaging prevents corrosion without having to treat the metal with oil, grease or paint.

Corrosion prevention through the right packaging solutions

Corrosion is a significant problem in the handling, storage and shipping of products. Bare metal parts corrode easily. Temperature changes, contaminated air, sea salt and moisture, all create corrosion. All products with bare metal (bearings, engines, parts, electronic devices) need to be protected. Products in overseas transit go through a complex process of loading, unloading, manipulation, warehousing and control. So many parameters can influence the quality of the metal. The highest care is needed for a problem-free arrival. Nefab has provided corrosion protection solutions for many industries over the years. Through our competence and global network, Nefab can provide a customized solution anywhere in the world, giving customers the ability to dispatch products worldwide without humidity or corrosion damages.

-

Film

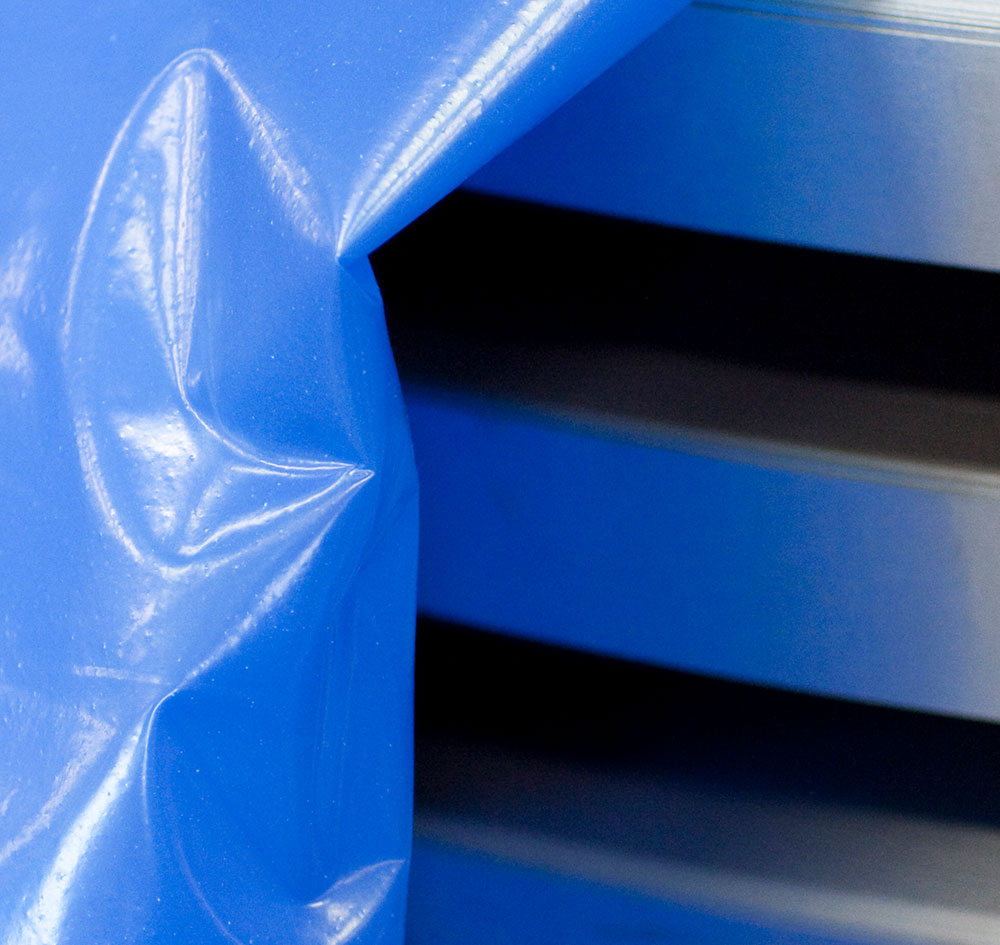

In some applications when products are not too sensitive to corrosion, protection is only required for very short storage or when the level of humidity in the environment is low, a combination of standard plastic film + desiccants and/or VCI emitters may offer enough corrosion protection.

-

Aluminium barrier and dessicant

Aluminium barrier material can be used as packaging in combination with desiccants. After a product has been packed, the air is pumped out and the desiccants absorb the remaining moisture. Aluminium barrier foil has a considerably lower water vapor transmission rate than bags made of LDPE or HDPE and reduces the required amount of desiccants in export packaging.

-

VCI

VCI is an additive that can be added to most common packaging materials. Once exposed to the air, the additive vaporizes in the air and deposits itself as a thin layer on metal surfaces. This layer prevents humidity from reaching the metal and the process of corrosion is prevented.