It is the go-to material to use when you need to protect products from shock and vibration. Foam can be made from a variety of materials, providing different advantages for many different types of products.

Why is Cushioning Needed?

As one of the most common types of material for providing protection for various products, cushioning foam can protect them from shock, which occurs when a package is dropped or when it is jostled or shaken in some capacity. Vibration is another concern that foam helps

protect against. While every package that is transported will be subject to vibration of some sort, certain products are more sensitive to vibration than others. The first step to determine the right cushioning solutions for your product is to find out its fragility.

Determining the Product Fragility

The first step towards determining the amount of cushioning a product requires is to establish the amount of mechanical shock the product can withstand on its own.

The fragility of the article is conventionally expressed in terms of a "G" value. That is, fragility refers to the maximum shock that an article can withstand without suffering damage. G is the gravitational constant and the cushioning G-value indicates the deceleration or negative acceleration (in this case, the braking, down to a speed of zero, of a dropped product hitting the ground) that an item can withstand without being damaged. The more fragile a product is, the less G’s it can withstand. The function and purpose of a cushioning is to extend the time for the speed reduction and thereby reduce the deceleration.

[ G is a unit for acceleration, equal to the acceleration of gravity: 1g ≈ 9,81 m/s2. Deceleration is “negative acceleration”, in this case the braking, down to a speed of zero, of a dropped product hitting the ground. The function of cushioning is to, through its compression, extend the time t(s) for this speed reduction v (m/s), thereby reducing the deceleration a (m/s2): A = v / t. The lower deceleration a (m/s2), that a product of given mass m (kg) is exposed to, the lower is the force impact F(N) on the product: F = m * a ]

Knowledge of the product that is contained within the packaging is critical. Field experience may indicate the types of damage previously experienced. Engineering judgment can also be an excellent starting point. Sometimes a product can be made more rugged or can be supported to make it less sensitive to damage.

Ideally, the fragility of a product is determined in a laboratory by subjecting it to a series of gradually more severe shocks (decelerations) to find the lowest severity impact that will damage the product. The highest deceleration, which did not cause damage, is then known to be the product’s G-factor. In this case, it is important to be aware of the cost for a destroyed product.

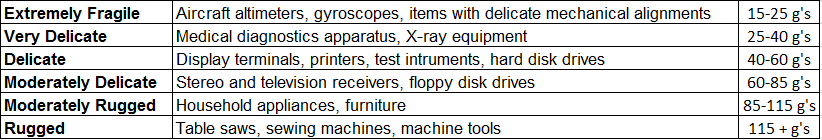

Approximate Fragility of Typical Packaged Articles

If the G-factor is estimated too high... the packaging will be under-designed and significant shipping damage is likely to occur. Please reference the above table for examples of sensitivities and G-values for commonly shipped objects.

It may be necessary to determine fragility levels for a product in various orientations, as it is not uncommon for a product to exhibit greater strength in one direction compared to another. The fragility levels should not be estimated, but defined through test data. If the G-factor is estimated too high, and the product is unable to survive as much shock as anticipated, the packaging will be under-designed and significant shipping damage is likely to occur. On the other hand, if the G-factor is estimated too low, and the product can withstand more shock than anticipated, the packaging will be over-designed and unnecessarily large and/or expensive. In other words, it’s very important to accurately determine the G-factor.