- News & Insights

- 2022

- Why fiber-based packaging is a solution for sustainable supply chains?

NEWS & INSIGHTS

Fiber-based packaging

Why fiber-based packaging is a solution for sustainable supply chains?

Scientific data shows that we are consuming nearly twice as many natural resources than the Earth can renew during a 12-month cycle.

Scientists can even estimate the exact day when the demand starts exceeding the supply – last year it was July 26th, 2021. They call it the Earth Overshoot Day. With the climate clock ticking, both the industry and legislators are urged to come up with solutions to protect the limited natural resources.

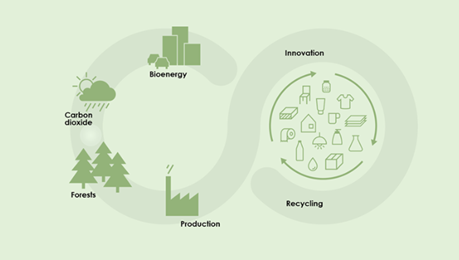

The natural solution is to switch to reusable, recyclable, and biodegradable materials – which is where fiber comes into play. It is a popular material used across various industries ranging from construction to packaging, and is estimated to grow at a CAGR of 3.6% by 2025 according to Transparency Market Research. Although fiber originates from trees, all of its parts are used according to their potential: the thick timber is used as a building material or for furniture, thin parts are made into paper, while the top branches and stumps generate bioenergy or biofuel. Trees are a renewable resource that, when properly managed through the process of growing and harvesting - are simply more sustainable than many other materials. A growing number of companies are sourcing raw materials from verified, sustainably managed forests to mitigate the consequences of utilizing finite natural resources.

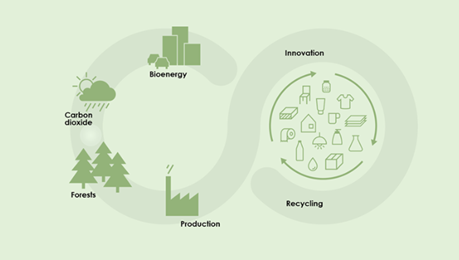

Both fresh and recycled fibers are used to produce pulp for fiber-based packaging. Fresh fibers mostly come from trees, but they are not the only source; numerous applications make use of wheat straw, bamboo, or bagasse, for example. The recycled fibers, however, usually come from used and recycled packaging. Both fresh and recycled fibers offer desirable characteristics and are used for different packaging applications, therefore both are needed in the fiber loop. In fact, both types of fiber provide optimal protection from external factors, while minimizing the environmental footprint. Here is how.

Strong and reusable

Fiber-based packaging material takes advantage of the natural characteristics of the raw materials, both fresh and recycled fibers, to create durable packaging solutions while using minimal amount of natural resources. In fact, fresh fibers are stronger than recycled fibers and are used in more demanding supply chains, like in the case of heavy products shipped overseas. To achieve the same strength for fiber-based packaging, fewer fresh fibers are needed compared to recycled fibers. This can be a good solution for products shipped by air, where reducing the total weight is important. As a result, the lighter packaging reduces the environmental impact as well as the total cost. Recycled fibers, on the other hand, are used where the strength is not as critical, for example for last-mile shipment of e-commerce or consumer products.

Moreover, fibers can be recycled up to 7 times and are an important raw material for new packaging solutions. Although around 80% of all available fibers are recycled, still each time the fiber is being reused, it loses part of its strength. That is why the loop needs to be constantly refilled with fresh fibers to maintain the quality of the final product. Once the fiber cannot be reused anymore, it will be used as bioenergy, which is a perfect example of the circular economy.

Recyclable until the last fiber

Globally, 80% of all fiber materials are recycled. However, in some countries – like U.S. and Canada for example – the number can go up to 85% making it the most recycled packaging material currently available on the market. In fact, depending on the product requirements, fibers can be recycled up to 7 times. Keeping in mind that 76% of plastic packaging is not recycled and ends up in landfills (according to data from EU, EBB, EPA and Simapro), this is a game-changing advantage for both brands and end-users.

Fiber-based products are a part of the natural, circular eco cycle that begins and ends with photosynthesis. Thanks to active forest management, all the products can create a closed loop that absorbs, binds, and sequesters carbon dioxide. This way the packaging industry is one step closer to minimizing the environmental footprint of using fibers for industrial purposes (Forest Industries).

Green future ahead

Fiber-based packaging solutions are an attractive alternative for both short- and long-cycle shipments, even in the most demanding supply chains. This holds especially true for industrial companies with one-way flows that don’t have a closed packaging loop. In such cases, fiber is the most environmentally friendly and cost-effective solution.

With the growing legislative push towards sustainability across the globe, change is imminent. Fiber-based materials are a ‘safe‘ packaging solution with sustainability edged in their DNA.

At Nefab, with a continuous focus on eco-friendly materials, we are finding new ways to achieve greater sustainability in our solutions and smarter ways to reduce the environmental impact. Together, we can pave the way for a future with less packaging waste for our customers, for society, and the environment.

We save resources in supply chains, for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our sustainable solutions driving supply chains forward.

LEARN MORE

GreenCALC

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Sustainable Solutions

Engineered packaging for sustainable supply chains

Sustainable Materials

Fiber-based packaging and raw materials