Protection against shock and vibration

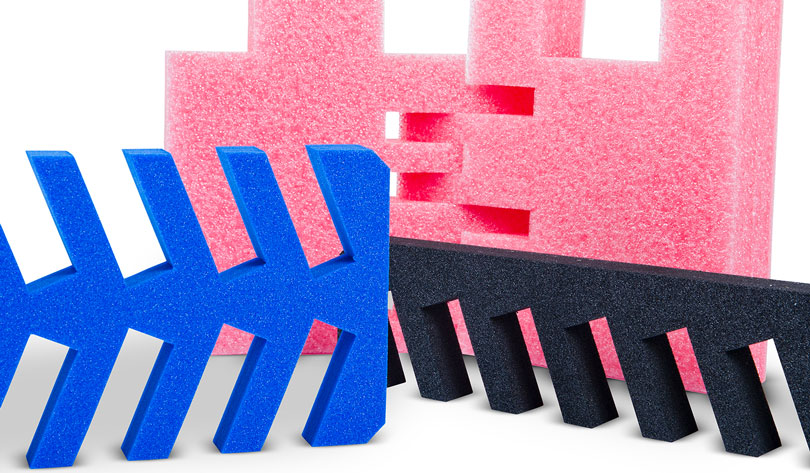

All sensitive products need the right protection against shock and vibration. Nefab offers, among other things, absorbing material which reduces shocks and vibrations and bracing, which separates products and holds them in place.

How does vibration affect the packaging?

Every mode of transport subjects the packages being shipped to some amount of vibration at various frequencies. In order to protect vibration-sensitive products, it is essential to determine the natural frequency of any component that is prone to damage from vibration and compare it to the vibration characteristics of the packaging design. The highest risk of damage occurs when the vibrations induced during transport coincide with the natural frequency of the product (or rather the critical component in the product), causing resonant frequency vibration excitation.

How to determine the appropriate vibration protection

For most vibration-sensitive products, making sure that the packaging design does not amplify (increase) vibration at the product’s natural frequency is enough to prevent vibration damage from occurring during shipment. For severely vibration-sensitive products, however, it may be necessary for the packaging design to actually attenuate (decrease) the frequencies of concern.

As with shock, the vibration characteristics of a specific design should ideally be tested, but may be estimated from knowledge about the vibration characteristics of the cushioning material.

Material response is often given in diagrams, which show performance for a thickness of a given material at its natural frequency. Note that for any frequency, one can estimate whether the packaging will perform in a direct coupling (unchanged vibration), amplification (increased vibration), or attenuation (decreased vibration) mode as a function of the static loading applied to the cushioning.

For more information

For more information on our solutions for shock and vibration, contact us today.