Plastic packaging solutions

A wide range of custom engineered plastic packaging solutions that drive efficiency, reduce environmental impact, and optimize supply chain costs.

A wide range of custom engineered plastic packaging solutions that drive efficiency, reduce environmental impact, and optimize supply chain costs.

Our engineered, highly customizable and protective plastic packaging solutions include trays, inserts, cushioning, large containers, rack dunnage, pallets, lids, and more.

With an extensive machine park covering diverse manufacturing processes, including injection molding, thermoforming, and cast urethane, we are able to meet a wide range of packaging needs.

We are advancing circular packaging solutions that minimize environmental impact while ensuring optimal product protection. Our circularity model prioritizes reducing material usage, reuse, and recycling.

Example of a complete packaging solution

1 - Lid; 2 - Trays; 3 - Inserts; 4 - Pallet

From concept through production, we deliver complete packaging solutions and services to optimize supply chains and reduce customers' total costs and environmental impact.

Our engineered, highly protective plastic packaging solutions include trays, inserts, cushioning, large containers, rack dunnage, pallets, lids, and more. We specialize in custom packaging solutions that can be complemented with standard offerings.

For our US-based customers, our online shop offers quick and easy access to our standard plastic packaging solutions.

Enjoy seamless ordering, fast delivery, and sustainable options – all in one place. Our product range includes thermoformed pallets, plastic inline trays, TPU buttons, brackets, and rack accessories – designed for durability, efficiency, and sustainability to support your operations.

We handle every step of the process in-house—designing, prototyping, testing, tooling, and manufacturing—by leveraging our extensive machine capabilities and the expertise of our plastic packaging specialists. With a diverse range of manufacturing processes, including injection molding, thermoforming, and urethane casting, we have the flexibility to create a wide variety of products using an array of resins.

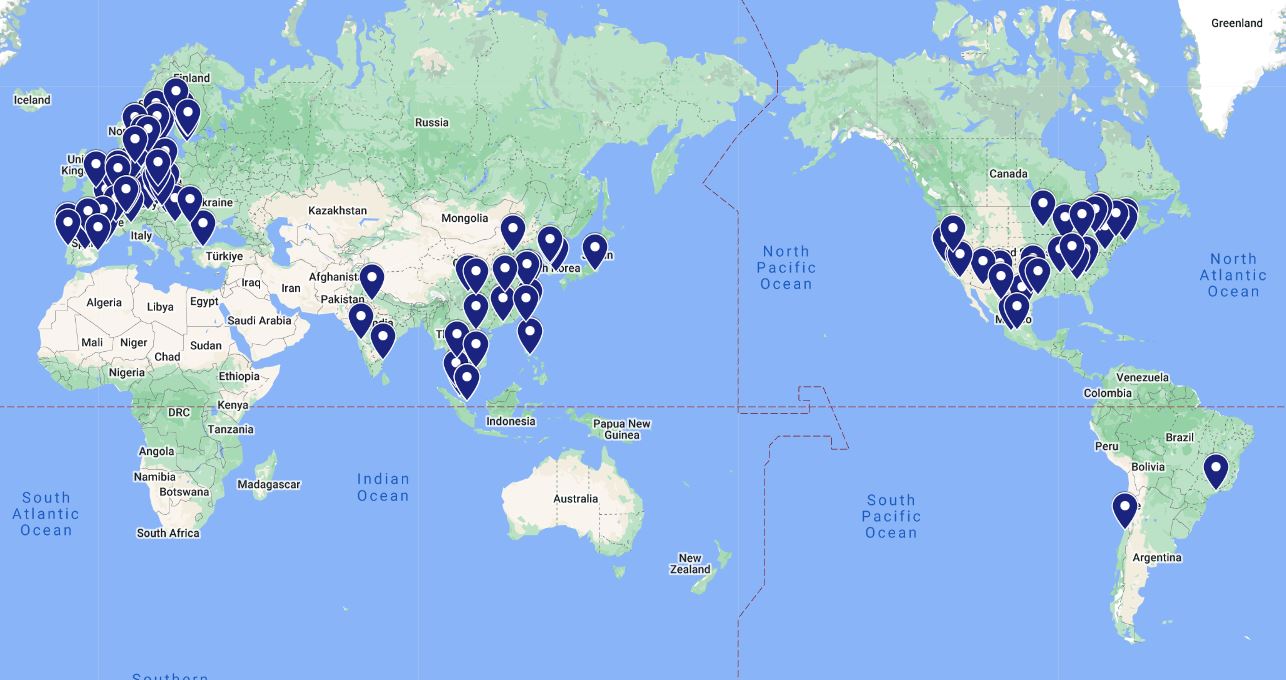

Nefab offers over 75 years of expertise in designing, manufacturing, and supplying industrial packaging, with operations in 38 countries and 130 locations. We provide global packaging solutions for industries such as LiB, E-mobility and automotive, telecom, datacom, semicon, and healthcare equipment, ensuring regulatory compliance and efficient supply chains. Combining global coordination with local expertise and capabilities, we deliver customized packaging and logistics solutions with personalized customer care worldwide.

Our circularity model prioritizes reducing material usage, reuse, and recycling, ensuring that packaging materials remain in use in the loop for as long as possible before they reach the end of their life cycle.

Nefab’s approach to reusable plastic packaging focuses on creating durable, lightweight, and space-saving solutions designed to minimize waste and reduce environmental impact.

The recycling of thermoformed packaging

1 - Packaging in use; 2 - Collection at end of life; 3 - Grinding; 4 - Grinded offcuts; 5 - Recycled material after re-extrusion; 6 - Production of new packaging

Nefab is dedicated to reducing material use, incorporating recycled materials, and enabling recycling.