In a previous blog, we described how you can combine packaging material to prevent short circuits in lithium-ion batteries and therefore comply with UN packaging requirements. But even though you have to prevent short circuit in LiBs at all times, it could still occur. Proper inner packaging is crucial to combat fires coming from short circuits. But to develop the right inner packaging, it’s essential to understand what happens to a battery if short circuit occurs. You’ll have to have an idea of the size of the fire and how (quickly) it develops. To get that understanding, a fire load test is key. Read on to learn more!

What is a fire load test?

A fire load test is a test that simulates a battery catching fire due to short circuit, while being contained in packaging. Well, simulate.. During a fire load test, we actually force short circuit on the battery by reorienting the terminals. So there’s a real fire, which is necessary to get an idea of what happens with a particular type of battery in a packaging that ought to be suitable for it. That’s the goal of a fire load test: to see if (the prototype of) your packaging is able to contain the fire.

During the test, the aim is to contain the fire, but sometimes a test might fail. Therefore, you can’t conduct them in places like regular production or storage facilities. For obvious reasons, you need a suitable testing location where a possible uncontained fire will not cause further damage. Confer with local authorities to determine a safe place to conduct your test. Check in with the fire department to make sure that they are aware of (the location of) your test, approve it, and possible extra measures needed in case of a failed test.

How to design lithium-ion battery packaging to submit to a fire load test

What materials can then be used to design packaging for lithium-ion batteries, which you can then submit to a fire load test. Let’s take a look at some examples:

The fire load test focuses mainly on testing the fire-suppressing material used for inner packaging, one common example is rock wool. Fire-suppressing material obviously prevents the fire from burning through the outer packaging. As a result, the contents of your box or crate will totally burn up. Rock wool is a great solution for batteries in smaller products, like notebooks. Unfortunately, that’s also its limit. Since the material won’t be able to contain fires coming from bigger batteries, it can only be used for the containment of smaller batteries.

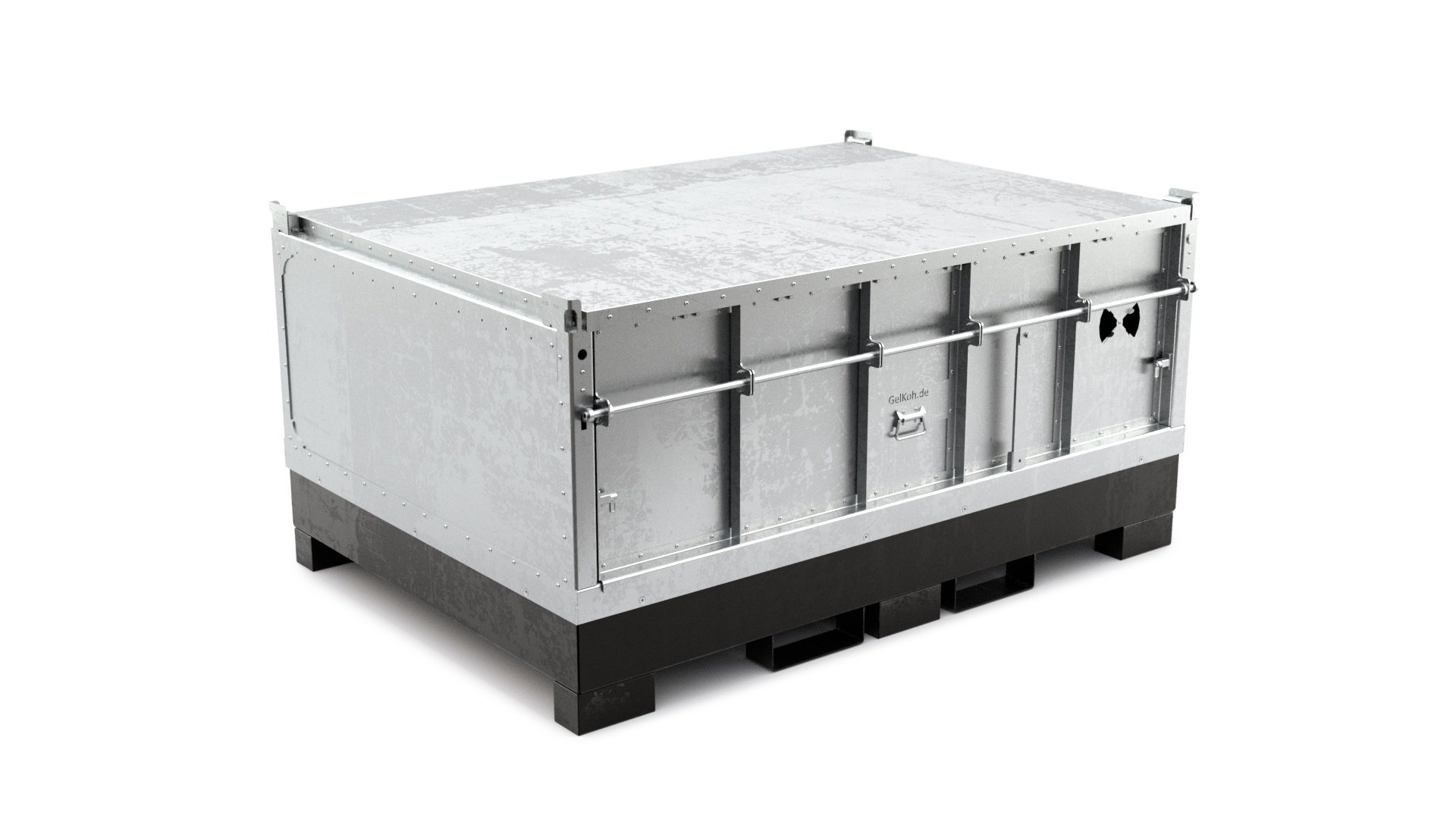

For bigger batteries, stronger materials are applied. In some of our cases for larger batteries, the inner packaging made from steel and Kevlar aramid. See figure 1 below for an example.

Figure 1: a Dangerous Goods Packing Group I certified box, with the possibility to load 1,400 kg.

Figure 1: a Dangerous Goods Packing Group I certified box, with the possibility to load 1,400 kg.

Other interesting solutions also exist, like fire extinguishment techniques. Passive systems triggered by increased temperature that takes away the oxygen from the battery. Oxygen is a necessary element for a fire to persist.

A burning or overheating lithium battery generates flammable gases. The buildup of these gases can cause the packaging to explode. With a smart internal design, you can enable pressure release through a valve without any flame penetration.

Once again, I would also like to point you to the article that we wrote earlier: how to combine outer and inner packaging material to safely ship lithium-ion batteries.

If you want to get updated when new articles about dangerous goods and lithium-ion batteries shipping get published, please subscribe to our blog updates in the top right corner of this page!

Also check out this article, where we explain how the select the right packaging material for your LiBs.

You can also read this customer case to see how we helped a customer with the right packaging solution for damaged batteries.

Take a look to see how we reduced this customer's cost of logistics with an efficient and compliant Lithium Ion Battery packaging solution — download the free case here:

Download the Lithium-ion Battery customer case

Find out how we reduced our customer's cost of logistics and environmental impact with an optimized and certified Lithium-ion Battery packaging solution

Download