An imperative issue demanding the attention of every business leader is the mitigation of their company's environmental impact. Realizing that climate tipping points are more imminent than previously assumed, each business leader ought to promptly implement sustainable practices. This proactive approach is crucial in averting the climate from surpassing the critical threshold of 1.5 degrees Celsius, beyond which irreversible changes may arise.1

To counteract that, companies need to achieve net zero emissions which means a fundamental transformation of the world economy. According to the World Economic Forum, transitioning to a more carbon-neutral future requires $13.5 trillion in investments by 2050.2 Despite digital technology sector being responsible only for a fraction of net global emissions (1-2%), tech companies make up most of the world’s wealthiest businesses with great potential to influence other industries.3 In fact, a few Advanced Technology players are already driving the change in their markets and prove that the evolution pays off, both environmentally and financially. Read on to learn more.

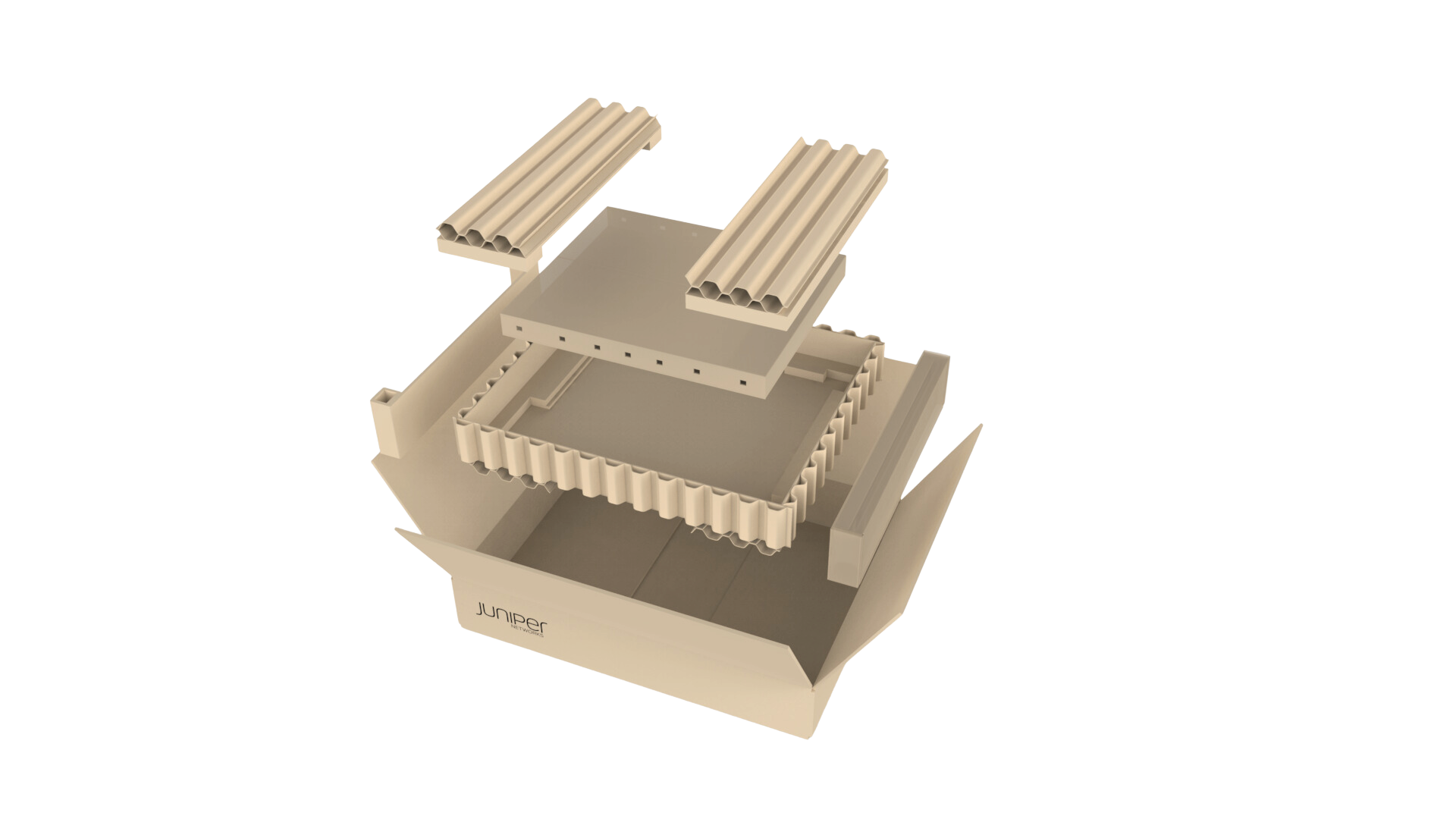

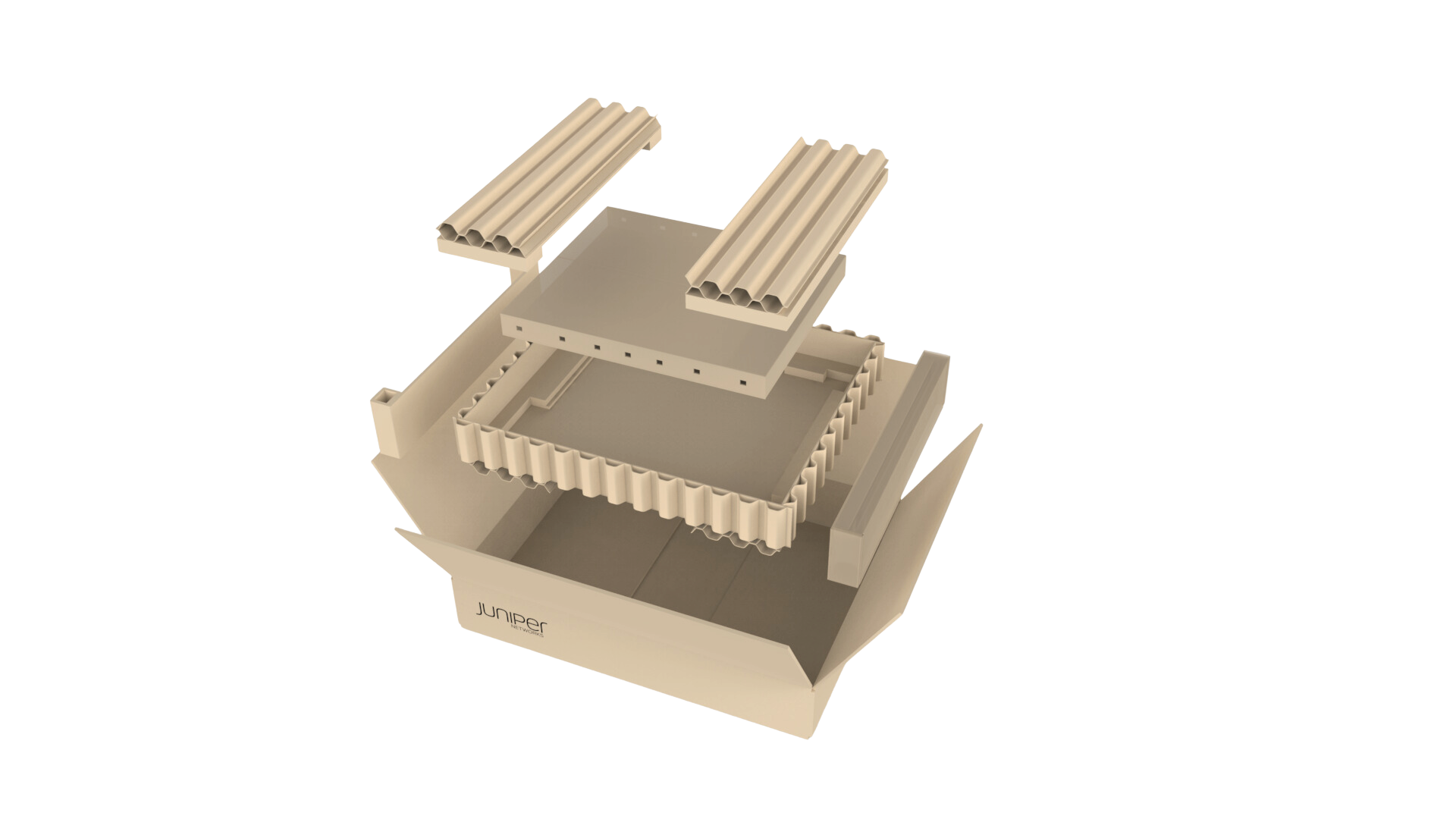

By switching to fiber-based packaging Juniper reached one of their key milestones to transition from virgin PE foam to recycled PE foam, demonstrating a commitment to reducing the environmental impact of packaging materials. (Source: Juniper)

Meeting Industry's Sustainability Goals

“Keeping in mind the climate clock is ticking, moving to 100% recyclable, fiber-based packaging, made of renewable source, is no longer a nice-to-have but a must-have,” says Johan Tegell, Group Strategic Product Director - Fiber-based Solutions at Nefab. A good example is European Union, where the revised packaging waste directive’s objective is to ensure that all packaging is reusable or recyclable in an economically feasible way by 2030.4 However, many Advanced Technology players from the region implement necessary changes already now to stay ahead of the curve.

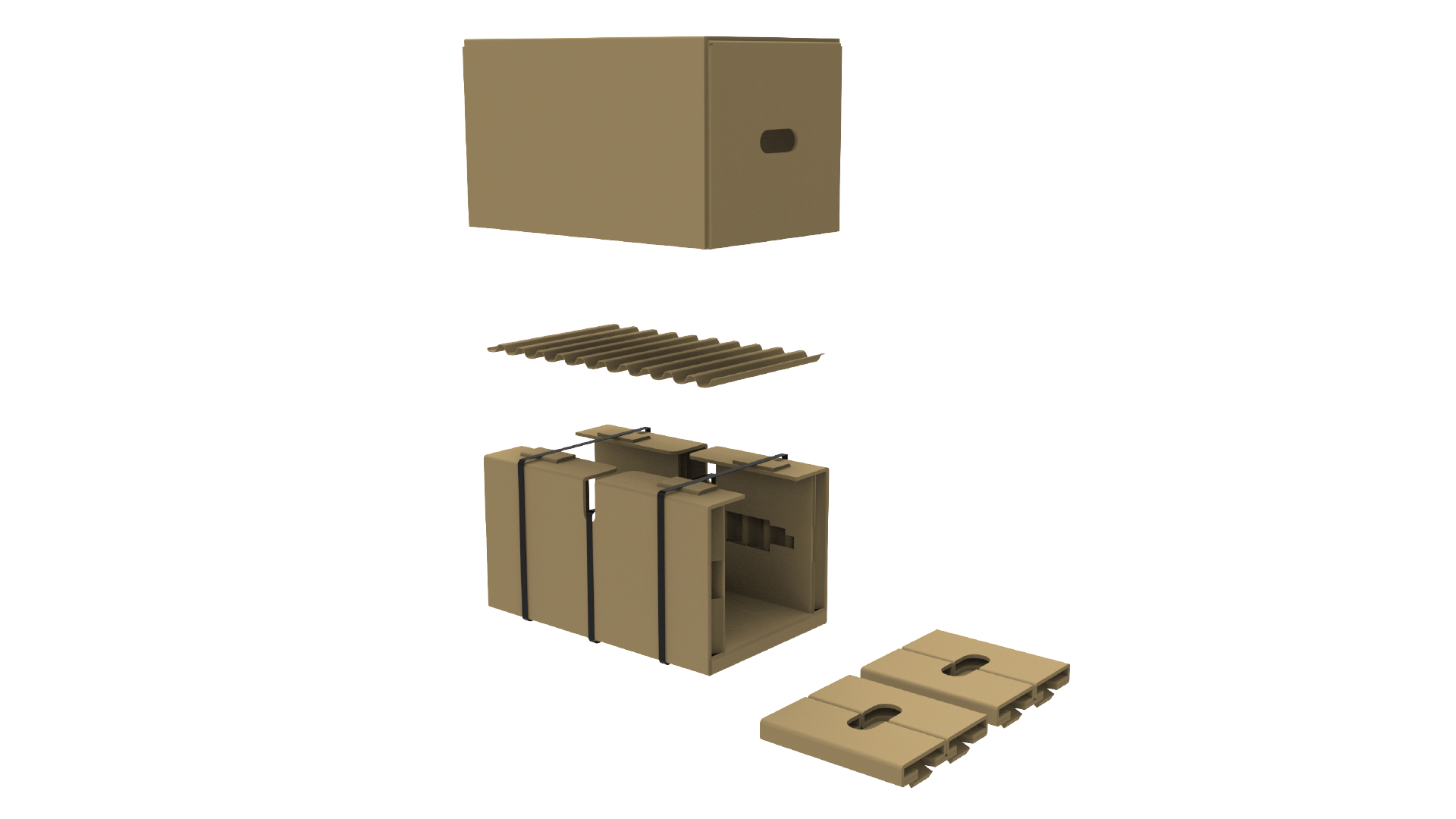

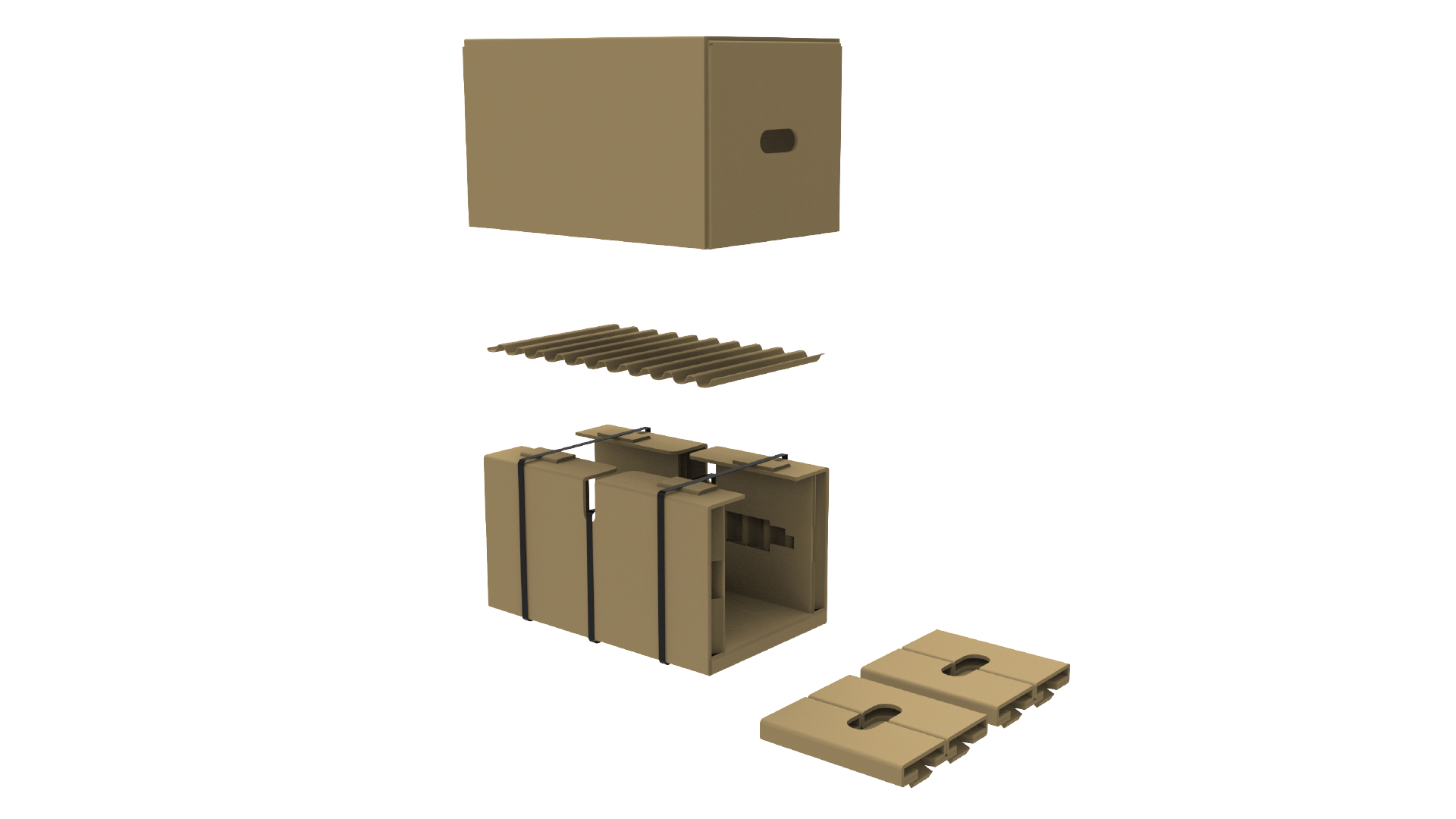

In line with its sustainability goals, Nokia has made a notable shift by implementing fiber-based packaging across its entire Lightspan broadband access nodes portfolio.5 The Finnish tech giant also recently received the prestigious Red Dot Design Award for their sustainable packaging solutions, showing that the transition pays off brand-wise.6 Another key player in communication technology, Ericsson, transitioned from single used plastics to fully recyclable, fiber-based materials for the packaging inserts of their Remote Radio packaging, in line with their Net Zero mission by 2040.7 Juniper Networks also embarked on the sustainable packaging journey, committing to eliminate plastic use for single-type compostable materials on systems packaging for smaller form factor products by 2025.8

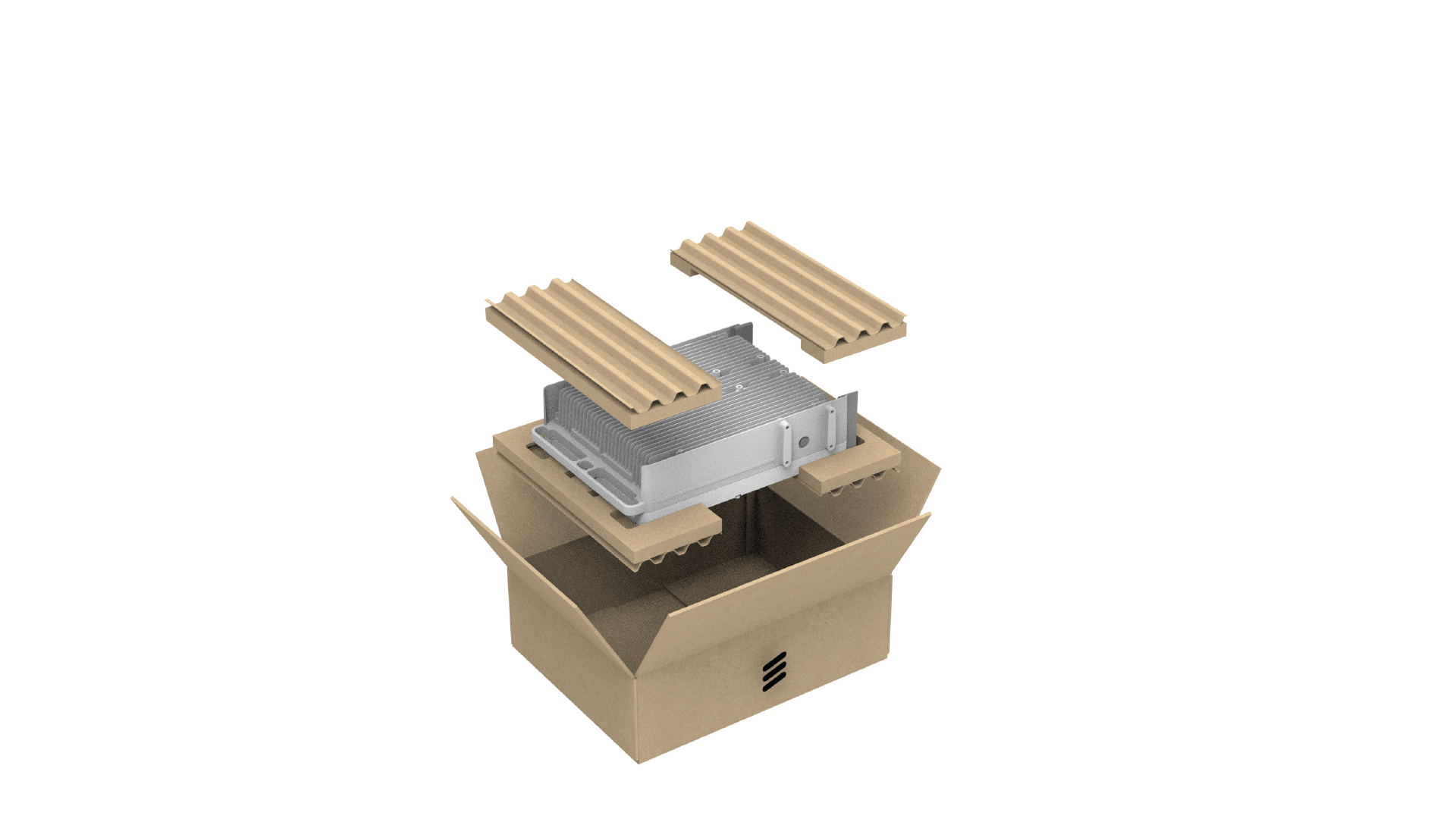

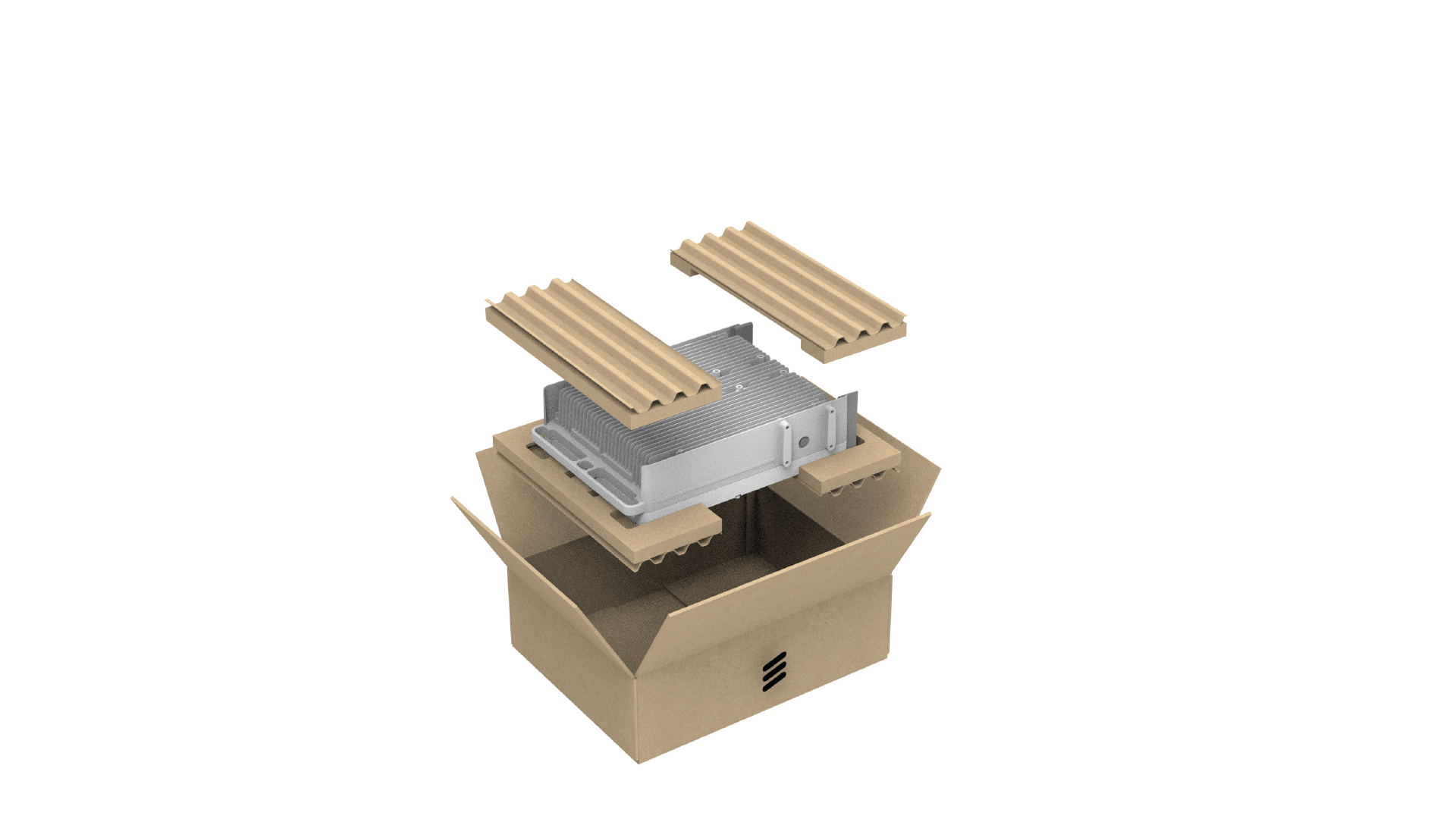

By switching to fiber-based packaging materials, Ericsson Remote Radio products are fully recyclable and reduce total plastic content from 20% to less than 1%. (Source: Ericsson)

Enhanced Product Protection

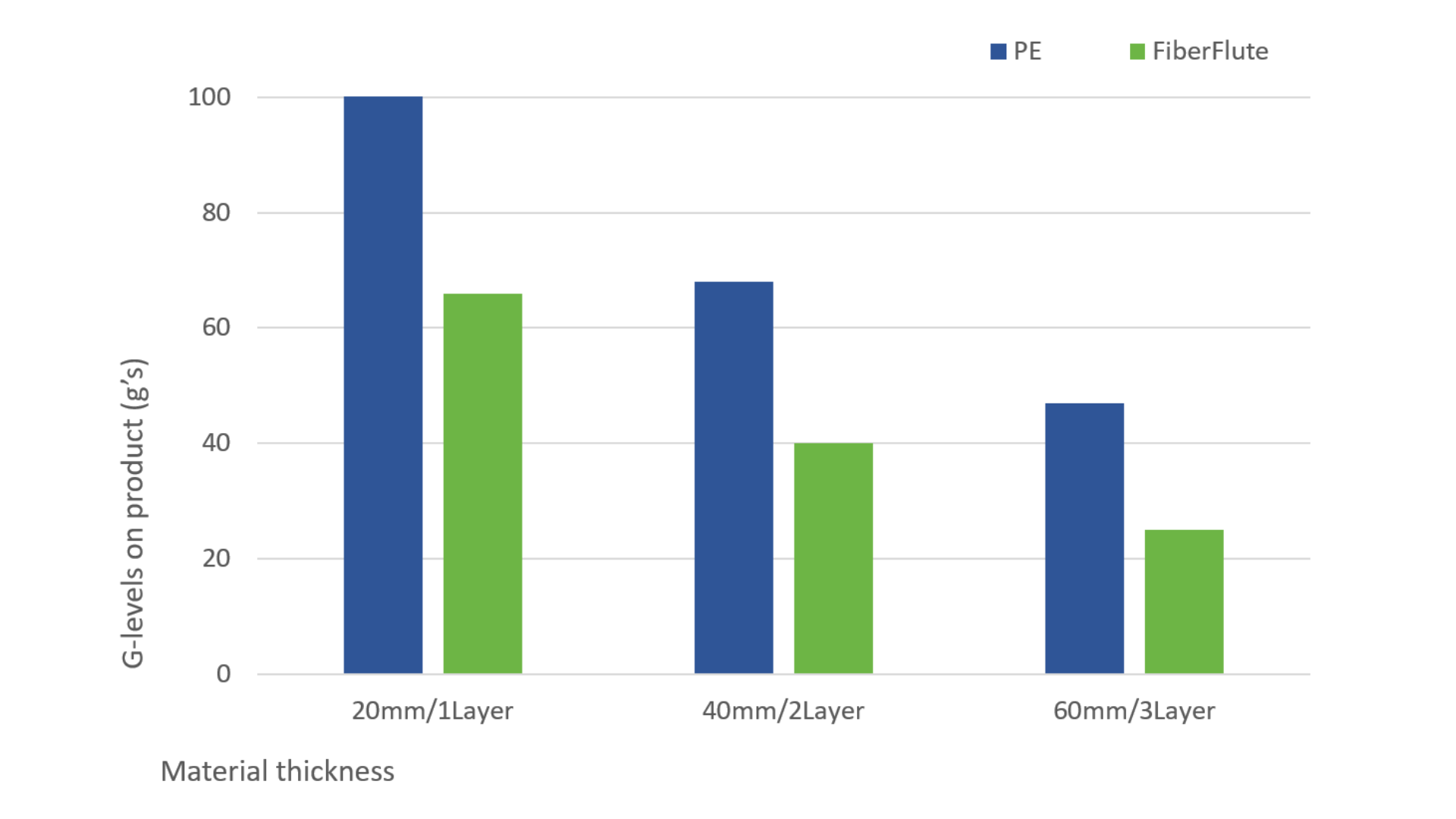

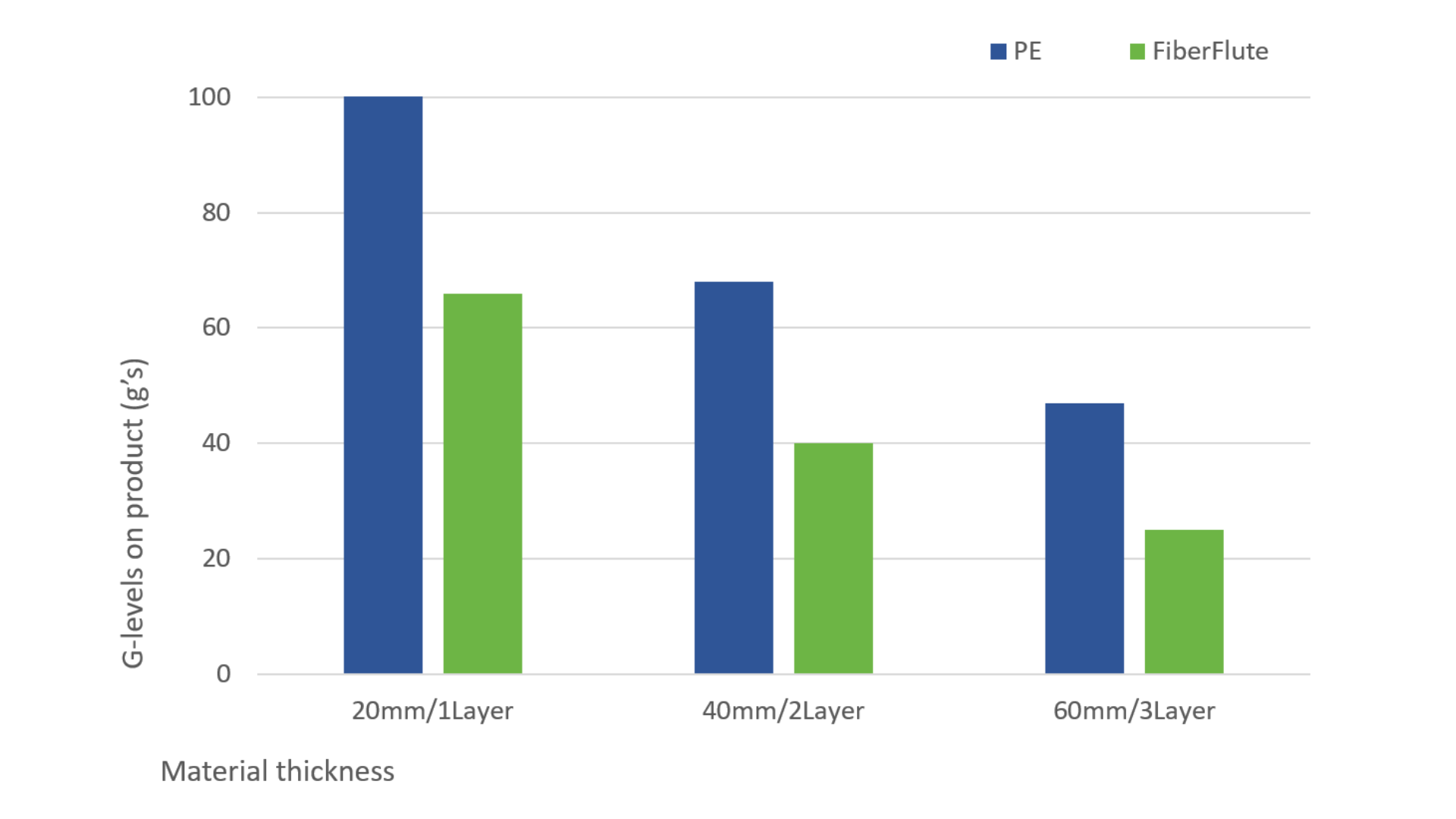

The examples from Ericsson, Juniper and Nokia proved that moving to sustainable packaging doesn’t come at the expense of product protection. “It’s been proven that fiber-based materials, such as FiberFlute, can absorb more shock with less material than polyethylene foam, in both dry and humid conditions, and can resist multiple drops, thus providing both financial and material savings,” added Johan Tegell.

In the Ericsson’s case, the fiber-based inserts include an anti-abrasion coating which protects the product’s surface during shipment without the need of additional plastic bags use. Additionally, they withstand up to 36 kg of load without compromising on product protection, packaging quality or functionality. For Nokia, the change of the buffer material which protects the product from dropping damage to fully recyclable fiber-based components resulted in 60% decrease in packaging size and a 44% reduction in overall weight.9 The shift to fiber-based packaging supported Juniper’s team in its mission to switch their packaging portfolio to fully recyclable paper that is designed to naturally decompose and limit unnecessary waste.10

In a comparative analysis between PE foam (30kg/m3) and Nefab’s fiber material (FiberFlute), the result showed 40-45% lower G-values. This means that less material is required to protect products when using fiber materials as compared to PE.

Making Supply Chains Greener & Plastic Free

“One thing that all three companies are trying to achieve is ultimately to eliminate plastics from their packaging”, added Johan Tegell. For Ericsson, the new fiber-based inserts reduced the total plastic content from 20% to less than 1%. In addition, the packaging size went down by 15 and 20%, respectively compared to conventional plastic inserts.

For Nokia, the new packaging eliminated non-biodegradable foam, plastic, bleaching, toxic materials, and chemical treatments, while replacing protective plastic covers with a biodegradable version. These change enabled Nokia to ship more products per pallet, plus reusing it in return shipments, and thus reduce CO2 emissions from transportation by up to 60%.11

For Juniper Networks the new solution supported the transition from foam to a paper-based solution, demonstrating a commitment to reducing the environmental impact of their packaging materials. The new solution allows for a 100% reduction in foam material for the product. The next step involves introducing 100% compostable and biodegradable packaging to further reduce package volume and pallet weight.12

In 2022, Nokia Networks received Best of the Best Red Dot Award for Sustainable Packaging Solution which uses fiber-based, biodegradable and plastic-free material that reduces CO2 emissions and packaging waste (Source: Nokia)

Natural Progression: A Step Forward

There is no doubt that the technology industry has set more ambitious goals for achieving net zero than any other sector. However, focusing on alternative packaging materials can support tech companies in meeting industry’s sustainability goals, enhancing product protection and ultimately making their supply chains greener and plastic free. As proved by the examples above, embracing fiber-based packaging solutions and switching to sustainable business practices are the natural steps in the right direction.

“We are extremely happy to see our customers lead the transition to a net zero future not only by reducing their emissions but also through implementing the innovative packaging solutions provided by our R&D teams. Only by working together can we achieve the ambitious but necessary goals to decarbonize and improve energy and resource efficiency to stop climate change”, summarized Anders Mörk, EVP, Advanced Technology, Nefab Group.

We save resources in supply chains, for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our smart and sustainable solutions.

LEARN MORE

GreenCalc

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Sustainable Solutions

Engineered packaging for sustainable supply chains

Sustainable Materials

Fiber-based packaging and raw materials