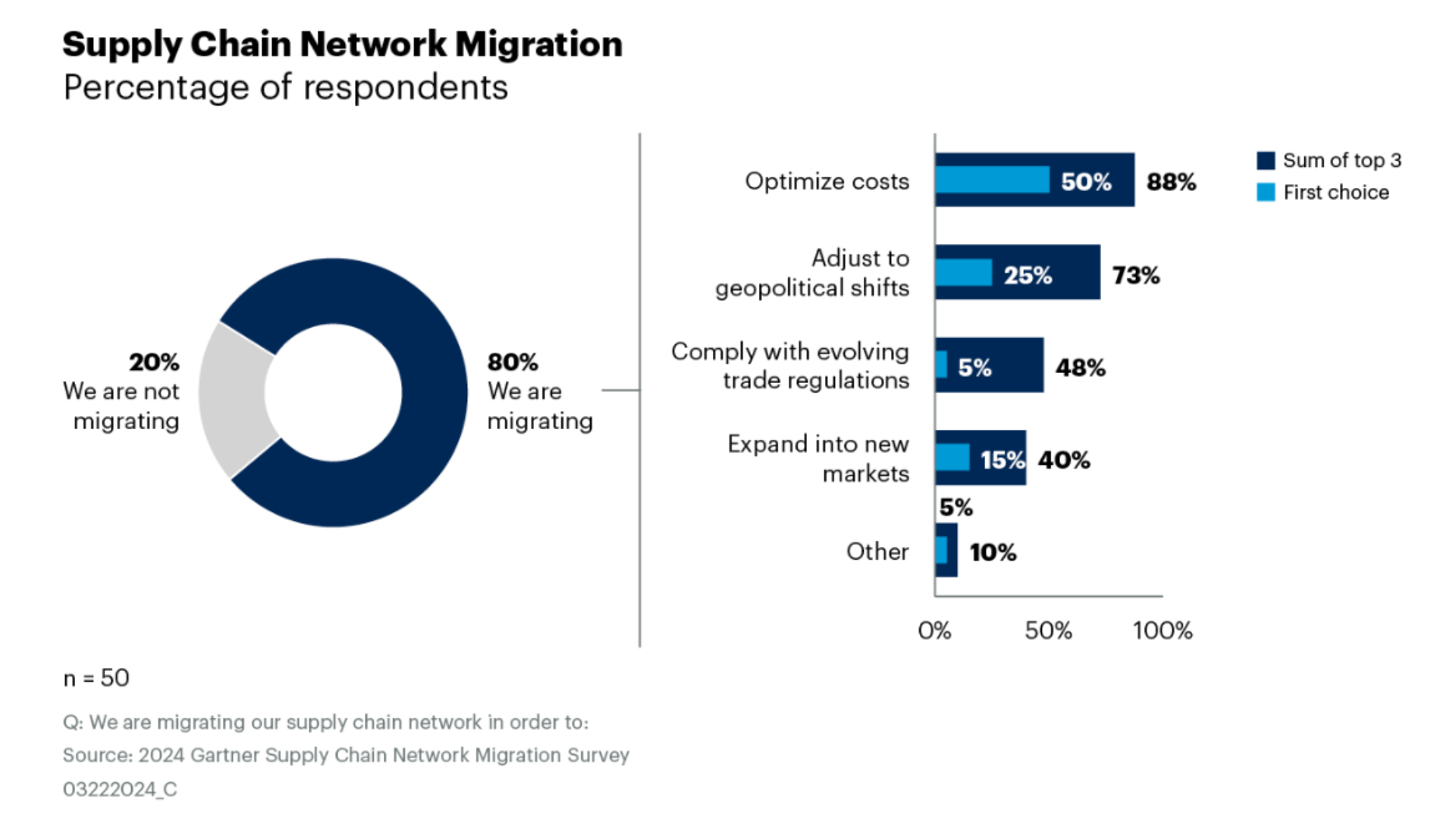

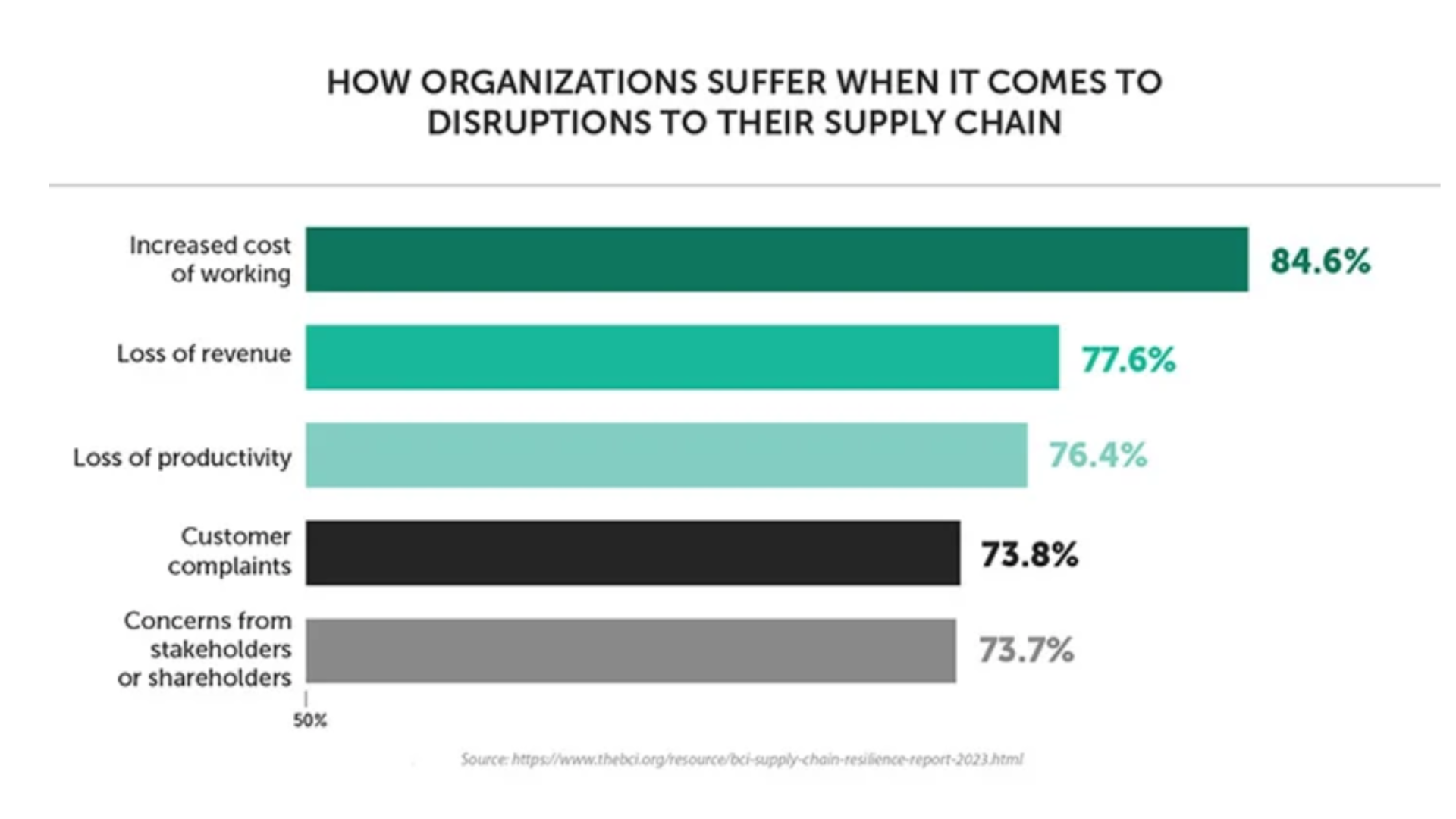

The new normal in global supply chains is dealing with disruptions. The industry has seen it all in the past couple of years: global pandemic, severe weather events, escalating geopolitical tensions, and intensifying economic conflicts. Some studies estimate that, on average, businesses across various sectors will experience supply chain disruptions lasting a month or more approximately every 3.7 years1 . To stay competitive in such an unpredictable economy, companies prioritize speed and agility in their operations, focusing on optimizing their supply chain configurations 2. Regionalizing logistics is one way to mitigate supply chain shocks. A recent Gartner survey indicated that 80% of chief supply chain officers plan to relocate parts of their network 3. In comparison, a McKinsey survey showed a rise in companies regionalizing their supply chains from 44% to 64% within a year 4.

Building a resilient supply chain has never been more critical. As businesses strive to stay competitive, they turn to regional supply networks to enhance responsiveness, reduce risks, and optimize costs. A key aspect of successfully implementing these regional networks is forging solid and collaborative partnerships with suppliers, contract manufacturers, logistics providers, and technology vendors 5. These partnerships are essential for sharing investment costs, managing risks, and ensuring a swift time-to-market. Read further as we will explore how regional supply networks are transforming the datacom industry and the role of strategic partnerships in building more resilient and cost-effective supply chains.

Recent surveys show that 80% of chief supply chain officers plan to move at least parts of their supply chain network. While this trend has been consistent over the years, the primary motivations have increasingly shifted towards reducing costs and mitigating supply network risks. Source: Gartner

Forging Strategic Partnerships

Successfully implementing regional supply networks involves identifying collaborative partnerships with suppliers, contract manufacturers, logistics providers, and technology vendors to share investment and risk mitigation costs. In an industry that never sleeps, a short time-to-market is essential 6. Once products are ready, a one-stop-shop partner is needed to quickly turn concepts into reality by designing, sampling, and testing packaging. The ability to produce consistent quality packaging across all geographies ensures a smooth deployment process, highlighting the importance of having a logistical partner with global reach and coordination capabilities.

When Nefab was approached by a global datacom company headquartered in the US, the brief was simple: design a reusable packaging solution for sensitive hardware and ensure it could be easily mass-produced in the APAC region. The project began in California, where Nefab's local engineering team designed three distinct packaging solutions that underwent rigorous testing at a local Nefab ISTA lab. The US team worked closely with the APAC team to ensure a smooth transition from initial design in California to mass production in Taiwan. This collaboration ensured an uninterrupted supply of subcomponents, safe assembly, and just-in-time distribution. By maintaining close communication with the customer, Nefab ensured both parties were aligned and well-informed throughout the process, resulting in a sustainable solution that leveraged locally available packaging materials and met regulatory compliance.

The packaging solution was developed and tested in California, and thanks to the global Nefab reach, it could immediately be replicated in Taiwan, which saved time and money. Source: Nefab

Reducing Costs and Boosting Sustainability

The cost-efficiency benefits that global networks once had over regional networks have diminished significantly as increasing global disruptions heighten the risks associated with longer supply chains. In regionalized logistical flows, distances are shorter, which improves agility and reduces transportation time. This proximity also enables businesses to explore new services typically unavailable in a global setting. Returnable packaging is one of the trending solutions in the industry because it is not only cost-effective and flexible but also improves companies' environmental footprints.

Returnable packaging solutions can be used throughout every supply chain step, including directly shipping products from the manufacturing site to another supplier and managing damaged returns. Upon arrival at the destination, returnable boxes are collected and sent back to the distribution point, where they are cleaned, repaired if necessary, and prepared for reuse. The success of this system relies on maintaining a limited number of distribution points, which helps track packaging and minimize losses. This approach optimizes the number of cycles in the flow and the amount of packaging required per shipment, increasing the return on investment. Besides the obvious environmental benefits, returnable solutions reduce transportation costs and provide complete visibility throughout the supply chain. By replacing one-way packaging with returnable solutions, businesses can significantly lower shipping costs, enhance product protection, improve worker safety, reduce their environmental footprint, and boost their brand reputation.

The supply chain disruptions are impacting companies’ bottom line and forcing them to adopt more cost-optimized solutions. Source: fictive

Strengthening Supply Chain Resilience

The shift towards regionalization in the datacom industry is reshaping how companies manage their supply chains in an increasingly volatile global environment. Businesses can enhance their agility, reduce costs, and boost sustainability by focusing on shorter supply chains, forming strategic partnerships, and leveraging returnable packaging solutions. These approaches mitigate risks associated with global disruptions and offer opportunities for innovation and growth. As the industry continues to navigate these changes, adopting a regionalized strategy will be vital to building more resilient, efficient, and environmentally responsible supply chains for the future.

With global expertise and local coordination, Nefab is committed to delivering innovative packaging solutions and expert supply chain strategies to help navigate disruptions and optimize logistics operations. Get in touch today to see how we can support your business and drive success in this challenging environment.