It is hard to believe that over 200 years ago, electricity and steam were the only forces propelling vehicles forward.1 Now, as the e-mobility sector rapidly evolves, we find ourselves coming full circle. Thanks to government incentives and the gradual phase-out of internal combustion vehicles in many countries, e-mobility stands as one of the fastest-growing trends in the automotive sector. Lawmakers across the globe are setting strict emissions targets and offering incentives to speed up the shift to electric transportation. This resurgence is not just a nod to the past but a clear vision of the future, where sustainable mobility is becoming the new norm.

Today, the mobility ecosystem is undergoing a rapid transformation driven by urbanization, the need to reduce greenhouse gas emissions, and technological breakthroughs like connected vehicles and short-range electric aircraft.2 Expectations are high from both regulators and consumers, who see the e-mobility sector as a pivotal force in decarbonizing the planet and revolutionizing the automotive industry. S&P Global Mobility predicts that electric vehicle (EV) sales in the United States could comprise up to 39% of total passenger car sales by 2030, with some even more optimistic estimates suggesting they may exceed 50% by the same year. 3 With global EV sales rising 4, the sector is set for substantial growth. However, navigating this dynamic landscape requires strategic planning, innovation, and the ability to overcome complex supply chain challenges. To dive deeper into the future of e-mobility, we spoke with Amaury Fruchaud, Global LiB & E-Mobility Director at Nefab. He highlighted three crucial supply chain areas the sector must focus on to stay ahead of the curve. What are those, then?

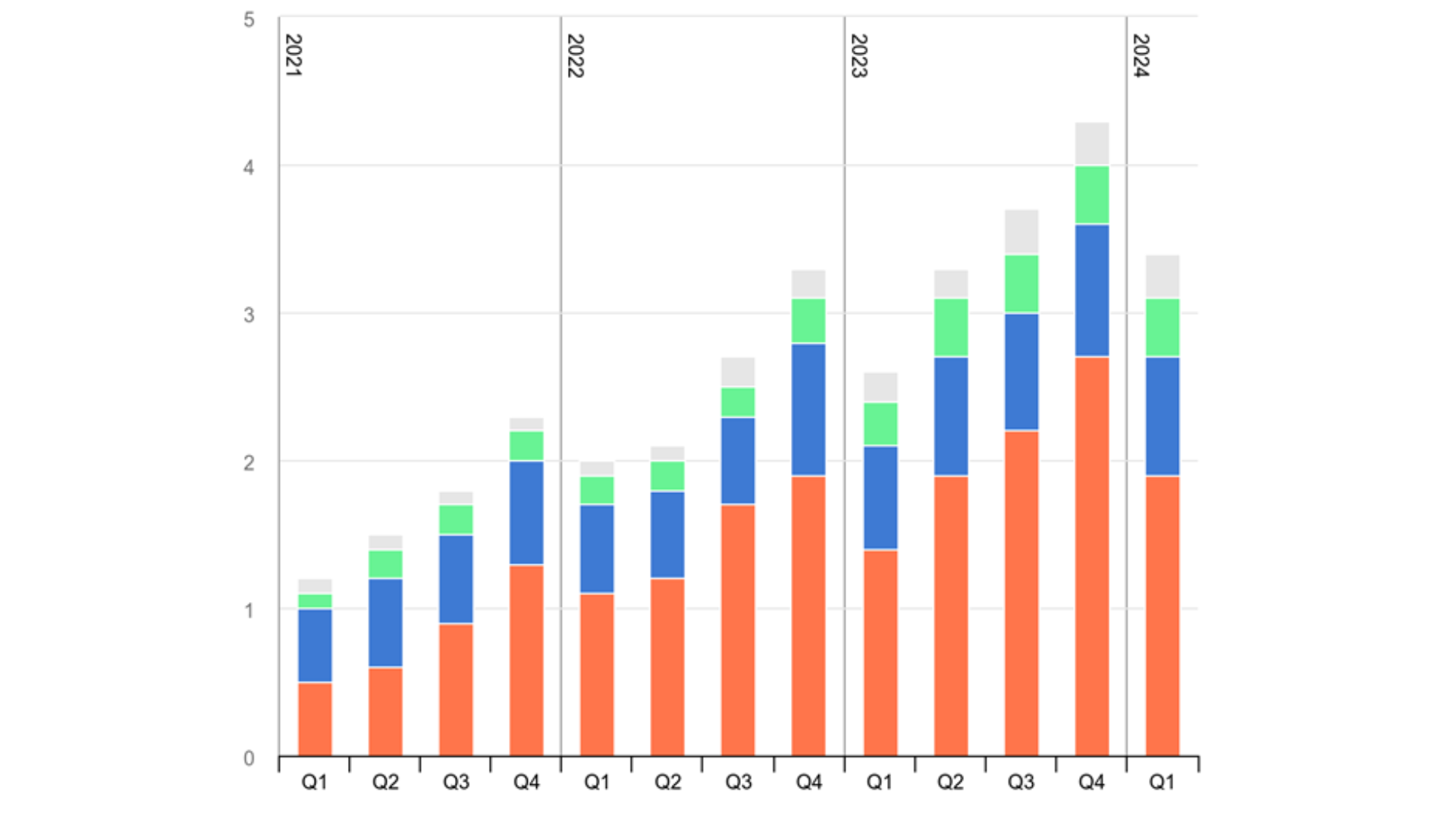

The demand for EVs is growing exponentially. The strong sales in the first quarter of 2024 exceeded the annual total from four years ago. Source: IEA (2024) 5

VELOCITY

For car manufacturers transitioning to all-electric vehicle (EV) production, timing is of the essence. A slow transition could lead to missed opportunities in the rapidly expanding market. 6 Staying ahead of trends and embracing innovative approaches are not just essential, they are the keys to success in meeting the industry's dynamic demands. As Amaury puts it, “Once a lithium-ion battery or new cutting-edge critical component hits the market, the race is on. Accelerating packaging development is crucial for our clients. Imagine customized regulatory-compliant solutions that can be quickly developed in one country and instantly replicated worldwide - that’s the speed level we aim for.”

The e-mobility supply chain operates globally, making it susceptible to numerous external factors. Ongoing geopolitical issues, extreme weather impacting energy outputs and infrastructure, and evolving trade dynamics all pose significant challenges. 7 As production scales to meet growing demand, the imperative to construct resilient and efficient supply chains becomes ever more pressing. Achieving agility requires coordinating supply chain services globally while also considering local perspectives to expedite processes and ensure regulatory compliance.

Technological innovation is revolutionizing the mobility sector, with more companies exploring disruptive technologies to drive progress and efficiency.

SUSTAINABILITY

With climate change and increasing consumer demands for sustainability, stakeholders are advocating for regulatory and business reforms to speed up the decarbonization of the mobility sector. The EU targets a 90% reduction in transportation emissions by 2050, with 30 million zero-emission cars on European roads by 2030. 8 In the US, the EPA aims for 67% of new light-duty vehicles and 25% of heavy-duty trucks to be electric by 2032. 9 In Asia, policies like Thailand's 2030 EV Production Policy and Indonesia's bans on fossil fuel vehicles by 2040 and 2050, respectively, support electric vehicle adoption. 10 "With regulations changing rapidly and resources scarce, our clients do not have time to dive deep and constantly follow the changes. They need inherently compliant packaging solutions," stresses Amaury.

As the race to zero-emission gains traction, the market is looking for logistics solutions that are both cost-effective and eco-friendly. In the linear economy, once the packaging runs its course and can no longer be utilized, it becomes waste. In circular systems, the packaging is designed to be repurposed within the so-called “take-back” programs at the end of its life. Plastic thermoforming or injected trays are great examples. Made primarily from recycled plastics and 100% recyclable materials, once their lifecycle comes to an end, they are collected, cleaned, extruded, and reused as raw material to produce recycled thermoformed trays. This closed-loop system keeps the plastic trays in continuous use, contributing to reduced CO2-eq emissions and total cost in the supply chain. To measure just how much switching to sustainable solutions saves resources, the industry is turning to Life Cycle Analysis tools, like Nefab’s GreenCalc. They examine various impact categories—such as Global Warming Potential (GWP), water and energy consumption, materials, transportation modes, and logistics flows—identifying areas for improvement to save costs and reduce environmental footprint. “Investing in sustainability isn't just about the business—it's about securing a better tomorrow for both yourself and the planet. Ensure your investment truly pays off by leveraging data-driven Life Cycle Analysis tools,” explains Amaury.

The Life Cycle Analysis tool enables you to measure the CO2-eq and financial savings achieved by adopting sustainable packaging and logistics solutions throughout the entire supply chain.

OPERATIONAL EFFICIENCY

One of the main barriers to global EV adoption globally is the price of the vehicle.11 As production costs remain high, mostly due to the rising prices of raw materials and shifting supply chains 12, manufacturers are looking for opportunities to save resources. One way of achieving that is by improving transportation efficiency. Managing logistics, materials, and compliance costs requires efficient packaging solutions that are protective, compliant, lightweight, and easy to transport. Unoptimized packaging practices in transportation result in inefficient use of cargo space, resulting in ships, trucks, and aircrafts "shipping air". More efficient packing solutions will help maximize cargo capacity while reducing the transportation industry's carbon footprint. “Optimized packaging solutions must be tailored to each product, ensure maximum fill rate, and maintain regulatory compliance, especially for dangerous goods, to avoid costly penalties," stresses Amaury.

Another way to free up capital is to leverage returnable packaging management solutions, where packaging is rented based on need or the pool size rather than purchased. On top of this, such pooling services are connected to an IoT platform that enables customers to monitor product transportation journeys. The collected data helps identify the right time for service, which part breaks most often and can be redesigned, and which suppliers are most likely to break equipment. By incorporating advanced sensors, the platform can monitor critical real-time environmental data such as shock, temperature, and humidity. This allows for quick response in case of sudden changes and subsequently guarantees the integrity of the shipments – critical when transporting LiB batteries or delicate electronic components. “We see many companies already upgrading their digital capabilities for better real-time visibility and demand planning. Soon, the demand for digital transportation in modern supply chains will surge, as connectivity enables logistics companies to cut costs significantly,” explains Amaury.

LOOKING AHEAD

The transport sector's transformation towards decarbonization is occurring at an unparalleled pace. The crucial challenge lies in integrating sustainability with economic feasibility through innovative technology and well-directed mobility initiatives. “In the e-mobility sector, the future is driven by partnerships rooted in innovation, global reach, and local expertise. In this ever-evolving industry, we don't just adapt, we innovate relentlessly to stay ahead. Because in the race for sustainability, only those who dare to lead will shape the future of e-mobility,” summarized Amaury.