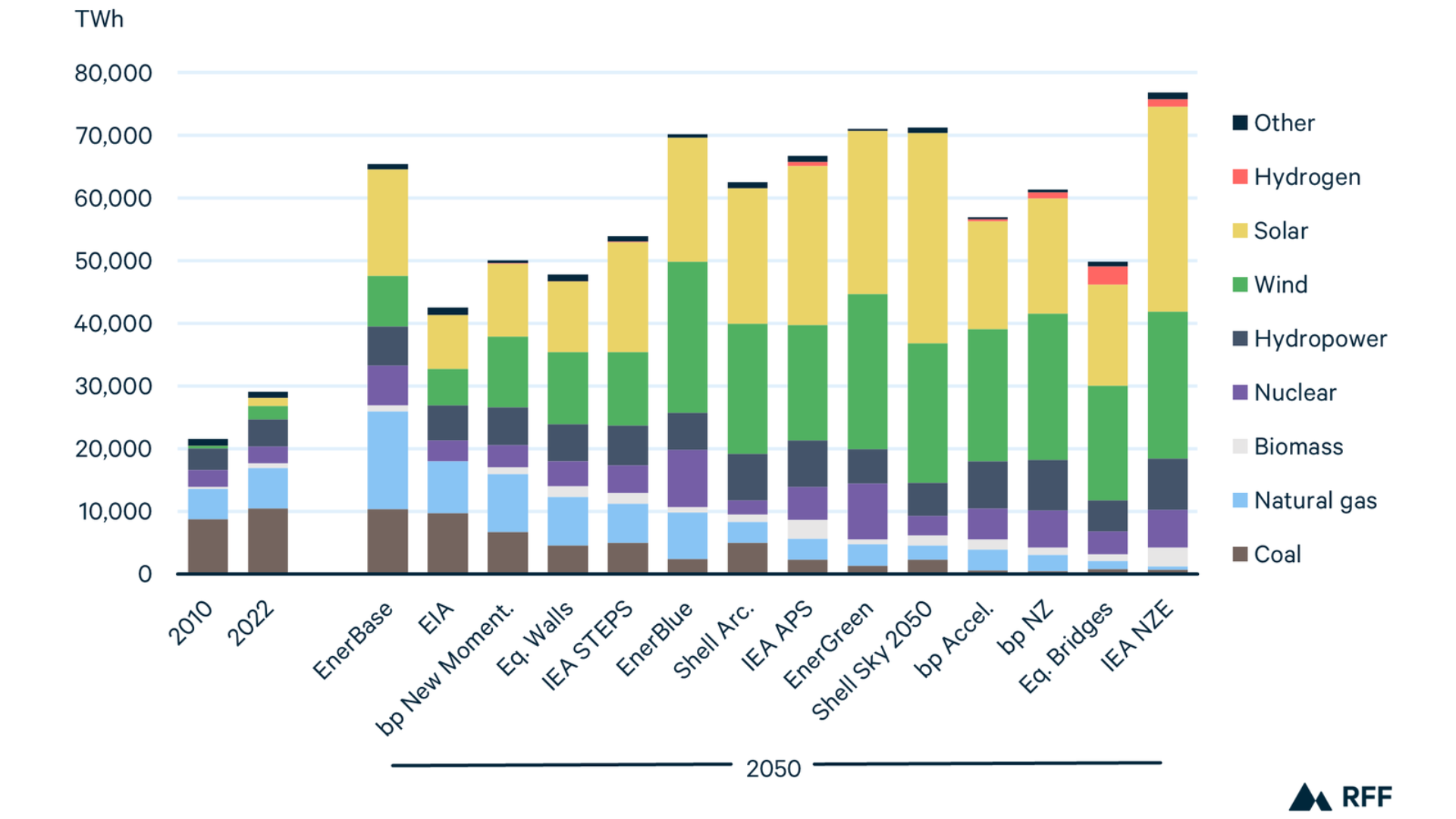

For 22 consecutive years, global renewable power capacity additions have been setting new records. 1 In 2023, this trend accelerated, with capacity growing by 50% to nearly 510 gigawatts (GW), largely driven by solar PV, which accounted for 75% of the new installations.2 The International Energy Agency (IEA) projects that global renewable power capacity will reach 7,300 GW by 2028, making renewables the largest source of electricity by 2025. 3 Despite all of that, further efforts are essential to meet the COP28 goal of tripling global capacity to at least 11 000 GW by 2030.4

Maximizing global renewable capacity is a complex logistical challenge, involving the construction of new infrastructure and the updating of existing grids. Vulnerabilities in the renewable equipment supply chain hinder the deployment of full capacity, making supply chain security a critical focus for the renewables industry in the coming decade and beyond. 5 Digitalization is poised to be a major factor shaping the future of the industry's supply chain, with smart solutions and custom software expected to boost its agility and resilience. 6 Follow along as we explore how digitalization can enhance the efficiency and safety of the renewable energy equipment supply chain.

Global Electricity Demand Rises Rapidly, Driven by Wind and Solar Power Source: Global Energy Outlook by RFF7

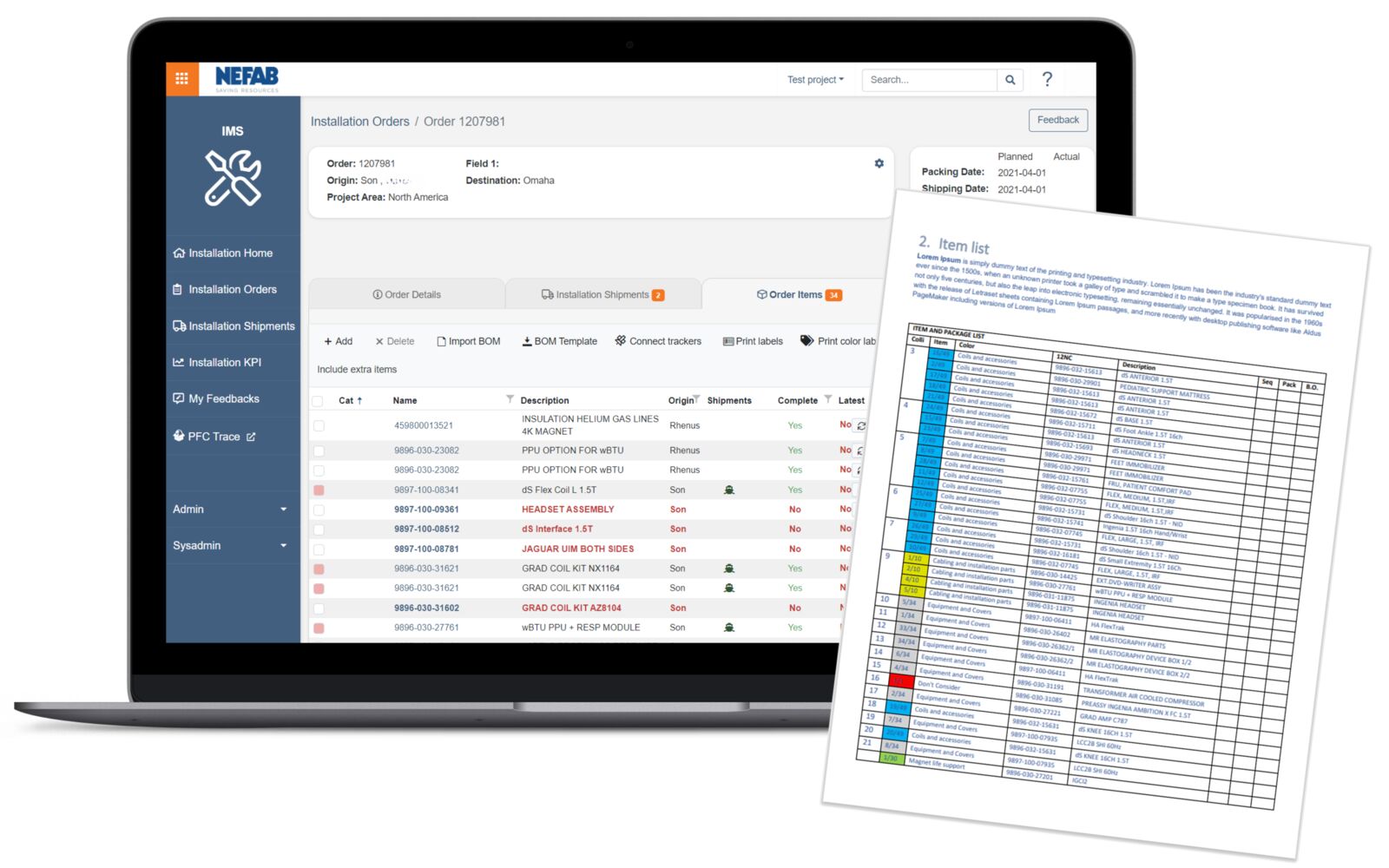

Seamless Delivery and Assembly

Delivering energy equipment to installation sites involves a complex orchestration of logistics and precision. Engineering teams often face challenges that hinder a "First Time Right" installation, with 20-40% of projects encountering issues due to missing, damaged, or incorrect parts. 8 To mitigate these problems, every phase of the delivery and installation process must be meticulously managed. Equipment must be transported in pristine condition, with clear labeling for easy identification, ensuring that nothing is overlooked. Proper sequencing is critical; each component must be ready for installation in the correct order to streamline the process and minimize delays. This attention to detail extends to the dismantling phase, where organized efforts ensure that parts are easily accessible when needed, reducing the potential for chaos at the site.

Modern installation management tools are revolutionizing the way energy equipment is installed. These tools help in planning each step, from determining the packaging requirements to sequencing tasks, ensuring that every article is accounted for before the installation begins. Real-time monitoring and proactive alerts play a pivotal role in maintaining the project's timeline by swiftly detecting and addressing any discrepancies, such as missing, damaged, or incorrect parts. With strategically placed crates and clearly labeled components, the assembly of bulky machinery becomes more manageable, allowing for a smoother, more efficient installation process. By leveraging these advanced tools and meticulous planning, engineering teams can significantly increase the chances of a "first time right" installation, ensuring seamless delivery and preparation of energy equipment.

Nefab’s Installation Management Track and Trace software revolutionizes installations with intuitive planning tools and seamless integration, enabling businesses to coordinate resources, manage shipments, and analyze performance for consistent success.

Increased Visibility and Product Safety

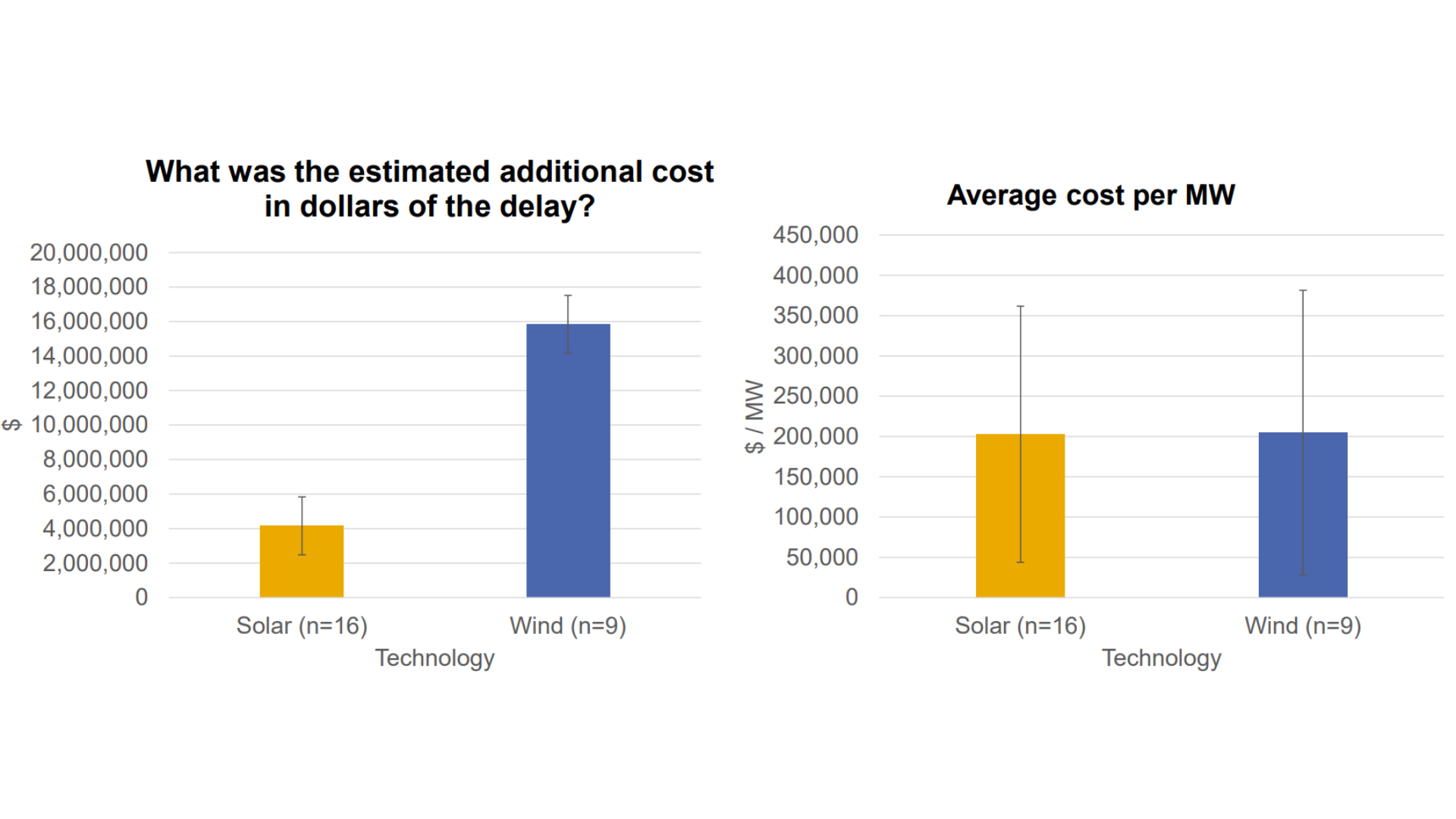

Almost all equipment and tools needed for power distribution, generation, or transmission are considered high-value assets due to their significant intrinsic value or their crucial role in business operations. Some of them, like wind turbines, are expensive to purchase and replace. At the same time, some assets may have a lower intrinsic value but are vital components of a broader business process. 9 If a crucial piece or tool is missing during the installation of a wind farm, for instance, the entire process can be halted, leading to costs that far exceed the actual price of the missing component. According to research, in the case of wind or solar project delays, the cost can amount to approximately $ 200,000 per MW. 10 This highlights the importance of even seemingly minor parts in the overall efficiency and cost-effectiveness of energy projects.

Track and trace platforms help control the valuable equipment across all transportation modes—air, sea, rail, or truck—by providing real-time monitoring and complete visibility into high-value assets throughout the supply chain. From order initiation to delivery, every step is meticulously tracked, enabling precise control and informed decision-making. Advanced tracking technologies and real-time monitoring detect potential issues like harsh environments or poor handling early, reducing the risk of damaged-on-arrival situations. Real-time visibility means one can react quickly to adverse environmental conditions or other potential issues, ensuring the safety and integrity of the high-value assets.

While the average costs for solar and wind project delays stand at $200,000, the estimated delay costs for wind projects tend to be four times higher than those for solar projects. Source: Energy Technologies Area, Berkeley Lab11

Enhanced Supply Chain Sustainability

Digital solutions play a crucial role in enhancing supply chain sustainability. For example, Nefab’s track and trace platform can calculate CO2-eq emissions for each order and segment of the journey, enabling informed decisions that align with sustainability goals. This platform allows users to optimize routes to minimize environmental impact and select eco-friendly transportation options, reducing their carbon footprint while safeguarding assets. This applies to packaging as well. Life Cycle Analysis tools, such as GreenCalc, are an excellent starting point for enhancing sustainability in the supply chain. They look at the packaging life from “cradle to grave” and provide proven and measurable evidence of the environmental impact of different packaging options.

At Nefab, sustainability is ingrained in our DNA. We understand the transformative potential of digital solutions in supply chain management and saving resources. By integrating cutting-edge technologies into our processes, we not only enhance the efficiency and cost-effectiveness of our packaging solutions but also significantly reduce their environmental footprint. Join us on this journey towards a greener, more efficient supply chain.