As global supply chains adapt to more-stringent environmental regulations and industry expectations, circularity is emerging as a game-changing approach in semiconductor equipment packaging. By extending the life cycle of packaging through reuse, repair, and recycling, businesses can significantly reduce waste, lower emissions, and drive cost efficiencies.

At the same time, digitalization is changing the face of the logistic and supply chains offering new ways to overcome operational and sustainability challenges. By leveraging digital services , companies can minimize waste, improve efficiency, and meet environmental targets without compromising on performance.

The question remains, can digital services and circular packaging work together to reduce environmental impact while maintaining operational flexibility?

Circular Packaging

Circular systems keep products, services, and resources in use for as long as possible. In these systems, nothing goes to waste, and nature is restored. Materials stay in circulation through “maintenance, reuse, refurbishment, remanufacture, recycling, and composting”1. Such an approach is not only good for the environment but also helps reduce operational cost. It is no surprise that nearly three out of every four global top executives surveyed by the World Economic Forum believe circular solutions will increase revenue2.

Circular packaging reduces material and resource waste by extending the lifecycle of packaging. It emphasizes reducing overall packaging, enhancing recyclability, and incorporating reusable designs where feasible3. A key example of circularity in logistics is the shift from single-use to reusable packaging.

In circular systems, materials stay in circulation through “maintenance, reuse, refurbishment, remanufacture, recycling, and composting.

Optimizing Semiconductor Equipment Logistics with Returnable Packaging and Pooling Services

Returnable packaging is designed for repeated use, creating a closed-loop system that significantly reduces waste. In the semiconductor equipment (SEMs) industry, this often involves sturdy containers, crates, or pallets specifically designed to safeguard delicate, high-value equipment during transport.

Pooling services simplify returnable packaging management by handling storage, maintenance, and just-in-time distribution, ensuring that packaging is available when needed without the burden of on-site storage or disposal concerns. For semiconductor equipment, integrating pooling with customized packaging solutions provides flexibility to adjust ad demand shifts, improving supply chain efficiency and storage constraints.

Thanks to pooling services damaged packaging does not go to waste. Service providers can inspect, repair, and reintegrate it into the client’s supply chain, or recycle the materials into new packaging.

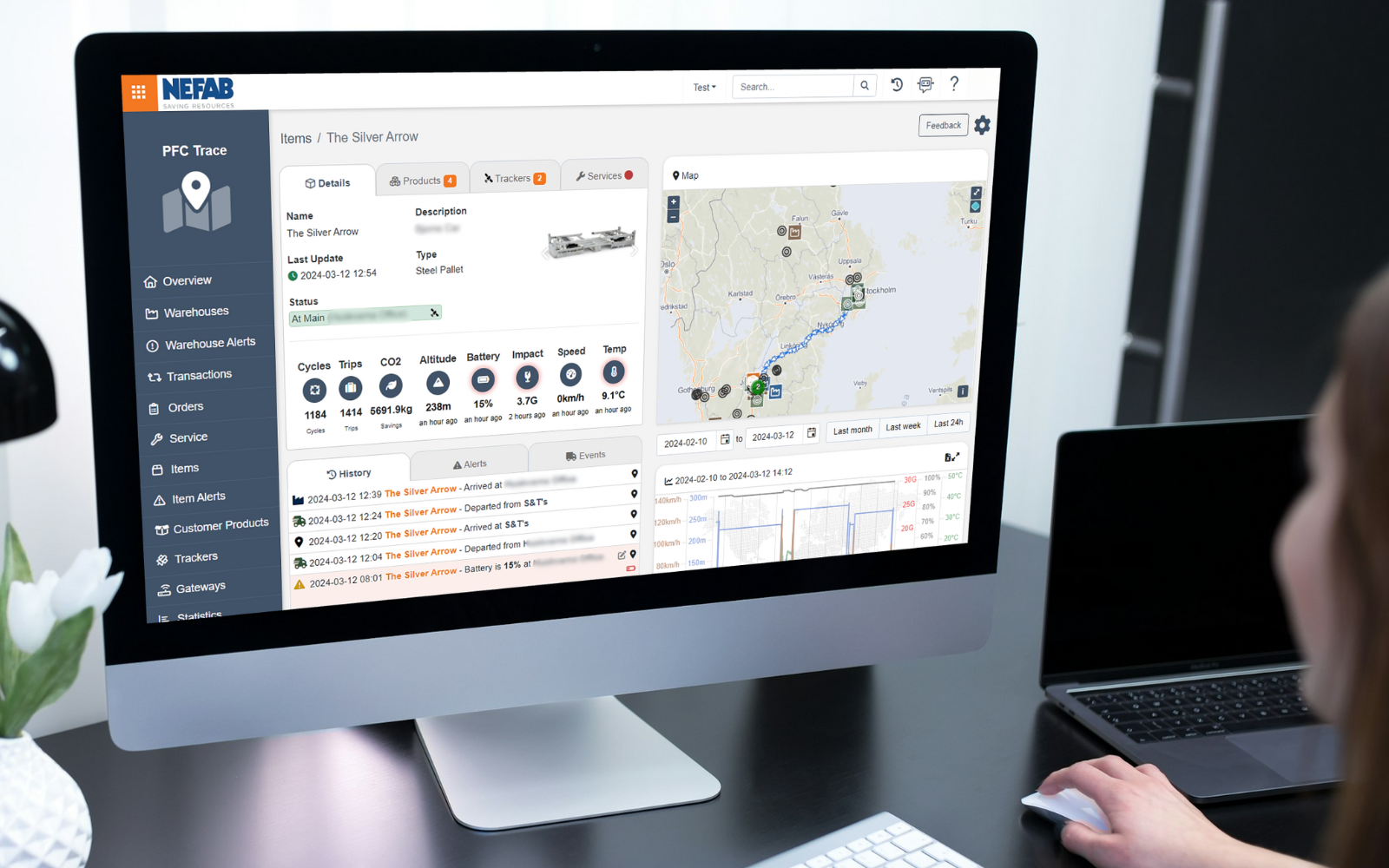

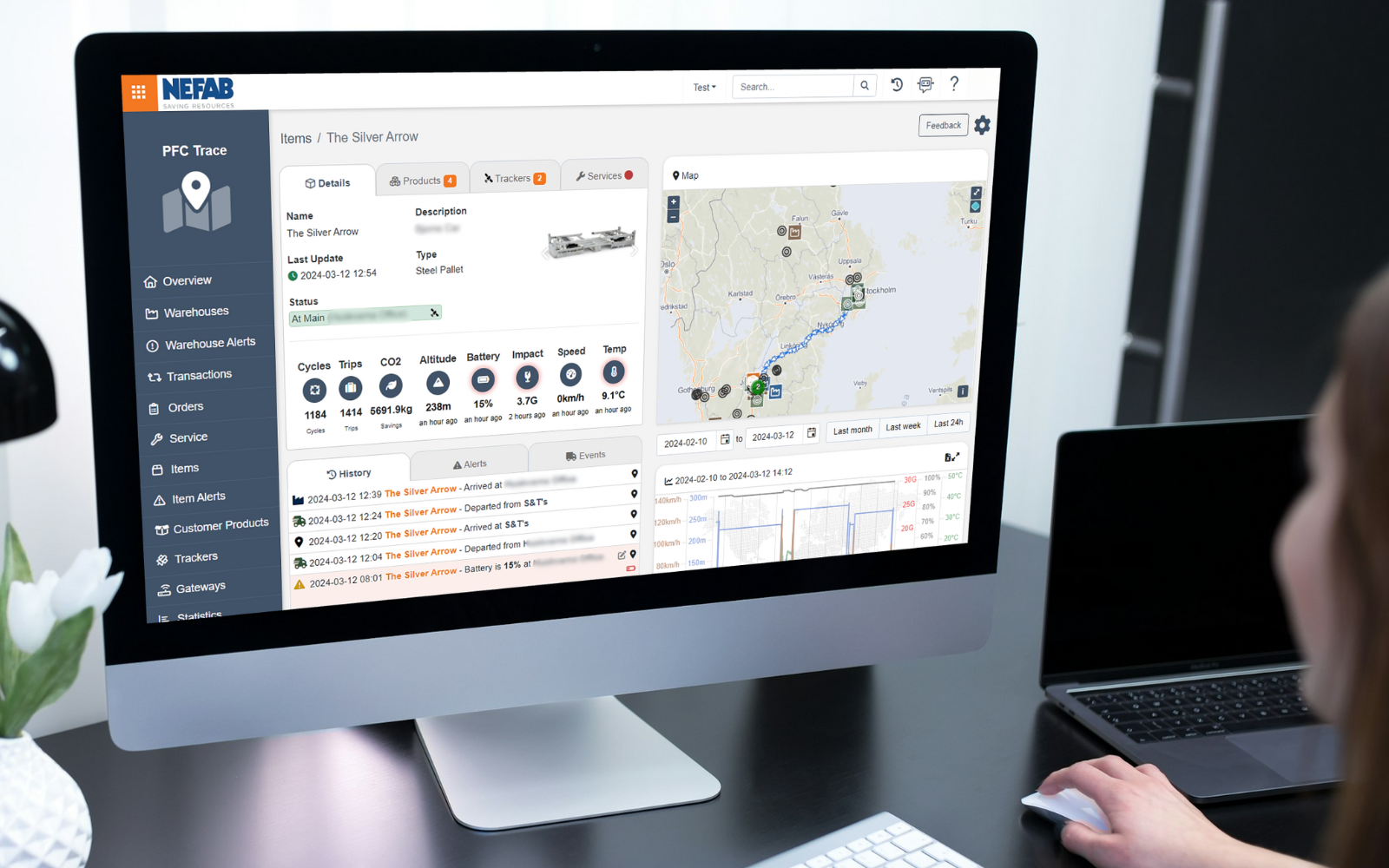

A well-managed reverse logistics system ensures that returnable packaging is efficiently cleaned, repaired, and scaled based on demand. Integrating digital tracking solutions enables real-time monitoring of returnable packaging, optimizing resource management and enhancing transparency across the supply chain.

How Digital Services Optimize Pooling in Semiconductor Equipment Logistics

- Enhancing Pool Efficiency: Digital services enhance pool efficiency by automating tracking, optimizing routes, and managing inventory. A robust platform simplifies implementation, reduces the need for security stock and shortens lead times. According to Nefab, this can shrink pool sizes by 25%4.

- Optimizing Shipping: Digital tools provide valuable insights to optimize shipping routes and select the most efficient transportation methods. They also improve the management of reusable packaging, ensuring smooth returns and minimizing losses.

- Reducing Costs and Environmental Footprint: By maximizing reuse and streamlining logistics, semiconductor equipment manufacturers can cut costs, reduce their carbon footprint, and make sustainable practices more achievable.

- Increasing Supply Chain Transparency: Digital Services integrated with pooling services offer a key advantage: real-time visibility across the logistical flows. Powered by smart packaging, these systems continuously monitor temperature, humidity, shocks, and other environmental factors to protect delicate and costly components from damage.

- Ensuring Product Safety: For semiconductor equipment manufacturers, IoT enabled smart packaging improves product quality assurance by tracking shipment conditions in real-time. In case of any issue such as excessive vibration or temperature fluctuations, proactive measures can be taken to prevent damage and maintain product integrity.

Smart packaging leverages cutting-edge IoT technology to deliver unmatched supply chain transparency, empowering businesses to streamline operations, reduce risks, and achieve greater sustainability and efficiency.

Digital Services For Measuring and Reducing Environmental Impact

Nefab’s digital services integrate proprietary GreenCalc - the Life Cycle Analysis (LCA) tool that evaluates both the financial and environmental impact of packaging and logistics solutions. By analyzing material usage, transportation modes, and energy consumption, GreenCalc helps businesses enhance sustainability and cost efficiency.

With data-driven insights, companies can adjust routes, shortened lead time, optimize cargo loads, and, consequently, reduce their overall carbon footprint. GreenCalc ISO-certified reports provide clear, measurable data on CO₂-eq savings and cost reductions, making it easier to quantify and showcase sustainability achievements. This is a game-changer for regulatory compliance and stakeholder reporting, giving businesses the tools to track and communicate their environmental impact with confidence.

Data-driven insights provided through GreenCalc process helps businesses enhance sustainability and cost efficiency in their supply chain.

The Future of Semiconductor Equipment Logistics is Circular and Smart

The answer is clear—digital services and circular packaging can work together to reduce environmental impact while ensuring operational flexibility. By adopting returnable packaging, pooling services, and smart tracking solutions, semiconductor equipment manufacturers can reduce waste, lower costs, and enhance supply chain efficiency—all while minimizing their environmental footprint.

Are you ready to future-proof your supply chain? Explore how circular packaging and digital services can transform your operations today.

We save resources in supply chains for a better tomorrow.

Want to learn more?

GET IN TOUCH

Contact us to learn more about our smart and sustainable solutions.

LEARN MORE

Solutions for the Semiconductor Industry

Sustainable Protection for Your Equipment

GreenCalc

Nefab’s own certified calculator measures and quantifies financial and environmental savings in our solutions

Global Engineering Network

250 engineering experts in more than 30 locations