Packaging Designing Process

With a 75-year legacy and commitment to saving resources, we engineer packaging solutions for your supply chain challenges.

With a 75-year legacy and commitment to saving resources, we engineer packaging solutions for your supply chain challenges.

Prioritizing holistic and efficient design and material selection, we aim to unlock savings and extend environmental impact reduction beyond packaging, including transport, handling, protection, and warehousing, while ensuring a high level of quality. Moreover, by utilizing our 3D-based engineering process, we enable efficient global collaboration.

By analyzing different elements of our customers' supply chains, including transportation, storage, and handling, we tailor packaging solutions to minimize overall logistics costs while maintaining efficiency and effectiveness.

By analyzing data and metrics, we can make informed decisions to improve and enhance your packaging solutions. This ensures high quality and performance for your packaging while minimizing cost and environmental impact.

Our sustainable packaging solutions are designed holistically to mitigate environmental impact across the supply chain. Our engineering teams follow Nefab's sustainability design guidelines when developing new packaging solutions.

A truly circular packaging design considers the whole lifecycle of a packaging product, from sourcing to production to distribution. Guided by strong sustainable design guidelines, we adhere to the principles of Reduce, Reuse, and Recycle (3R) in our packaging solutions. This ensures that our designs not only meet the highest standards of performance but also contribute to a more sustainable future.

Reducing the amount of materials used and resources needed to ship the packaging is the number one rule of the 3Rs approach in supply chains. At Nefab, we employ various strategies to achieve savings along this path, such as load optimization and efficient packaging handling. By reducing environmental impact during transportation, minimizing packaging material usage, and mitigating product fragility, we uphold our commitment to sustainability while enhancing operational efficiency.

Designing to reuse packaging throughout the supply chain cycle is an effective strategy for conserving resources. Nefab accomplishes this through three key methods. First, we prioritize the reuse of packaging multiple times, maximizing its lifespan. Second, we manage returnable pools efficiently to ensure optimal utilization. Finally, we select packaging that can be repaired and utilized across the entire supply chain, further reducing waste and promoting sustainability.

When selecting packaging, Nefab opts for materials with high recycled content and ensure they can be easily recycled again. By adopting a circular approach, we prioritize sustainability and contribute to a more environmentally friendly future.

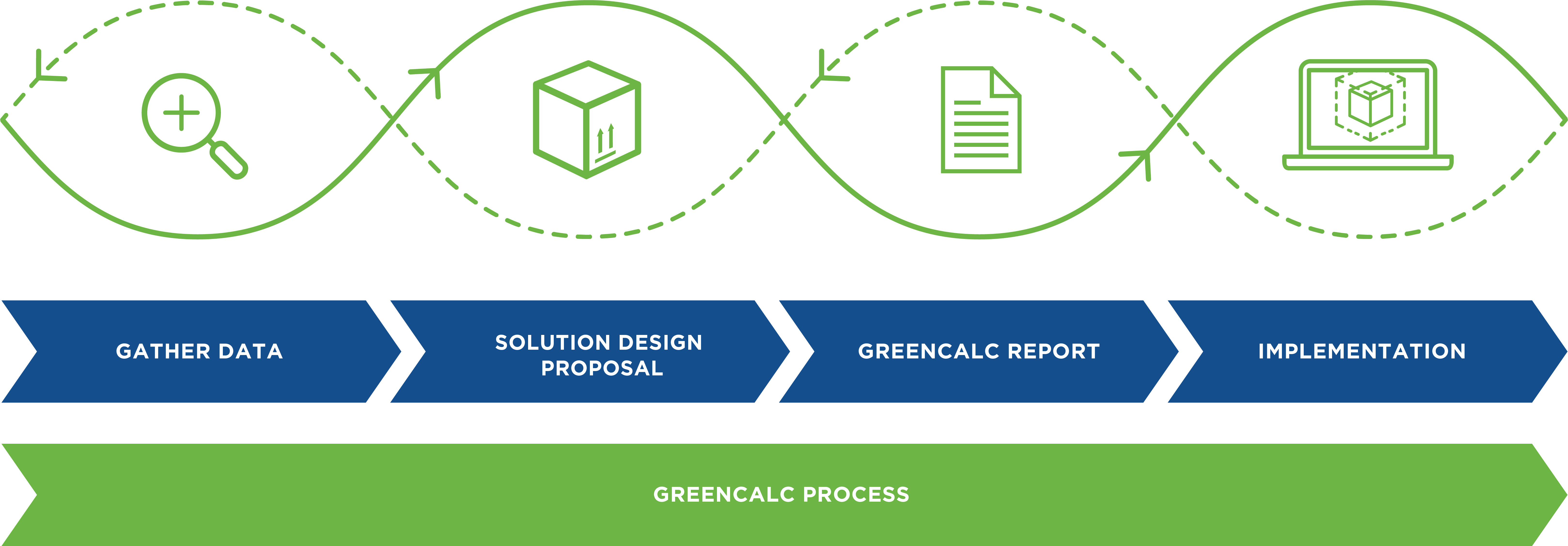

One of the key tools that support our optimal design process is GreenCalc – an innovative Life Cycle Assessment (LCA) tool developed by Nefab. GreenCalc empowers packaging engineers and designers to quantify the environmental impact and cost savings of a packaging solution compared to existing alternatives.

Strike a balance between ensuring packaging protection, reducing environmental impact, and maintaining cost efficiency. Download our eBook to unlock how packaging engineering redefines safety and leads to a sustainable supply chain revolution.

Join us on a journey of saving resources and learn about the latest trends, solutions, and best practices in sustainable supply chain management and discover smarter ways to reduce environmental impact and boost cost efficiency.

Contact us today to learn how our approach to design, test, and innovate can benefit your organization and help you stay ahead in a rapidly evolving market. Our team is dedicated to exploring and implementing innovative solutions that drive progress and efficiency.