Products

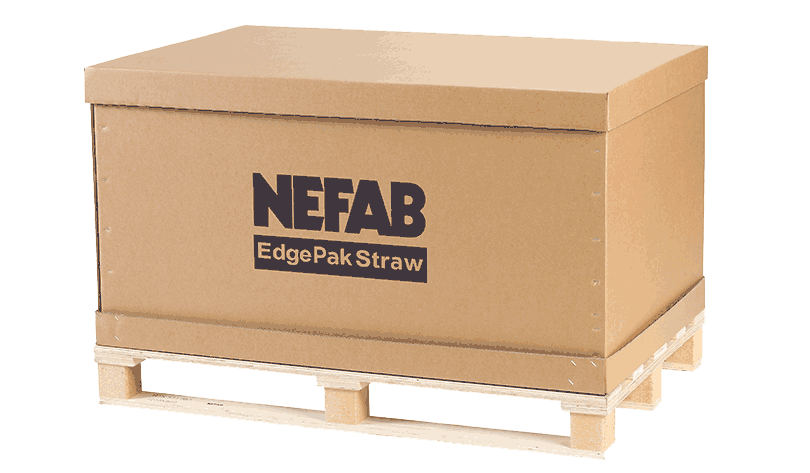

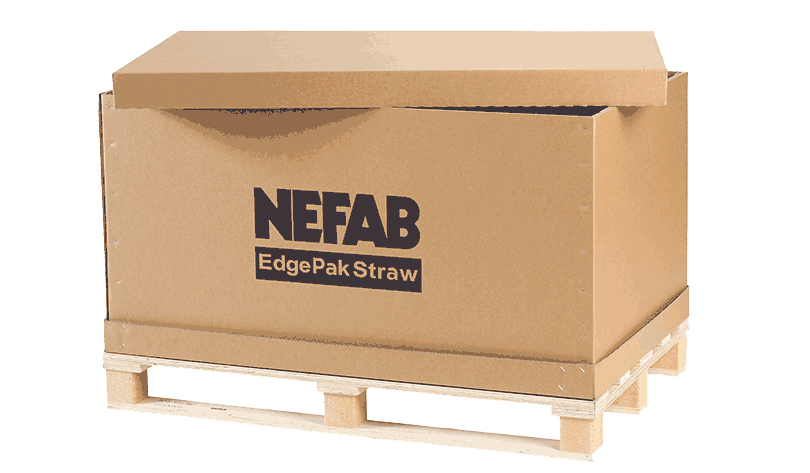

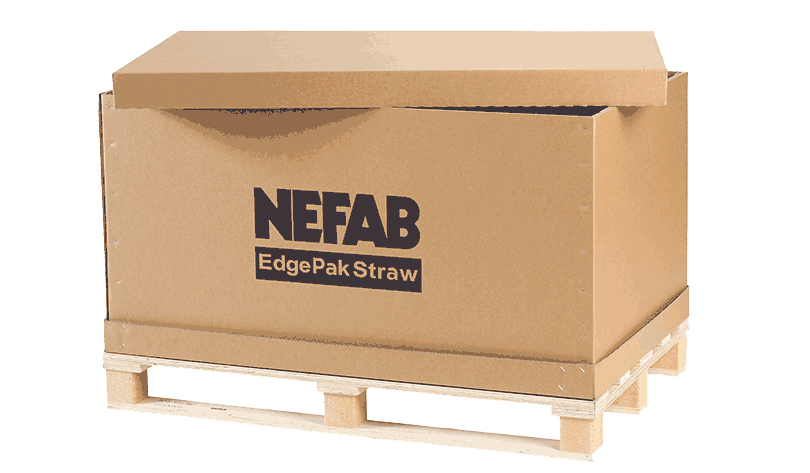

EdgePak Straw

Straw-based packaging solutions

EdgePak Straw is a solution that provides stacking strength and easy handling at a low carbon footprint. Its foldable corners are made from strawboard, creating a strong moisture resistant construction that can stack over 4 tons.

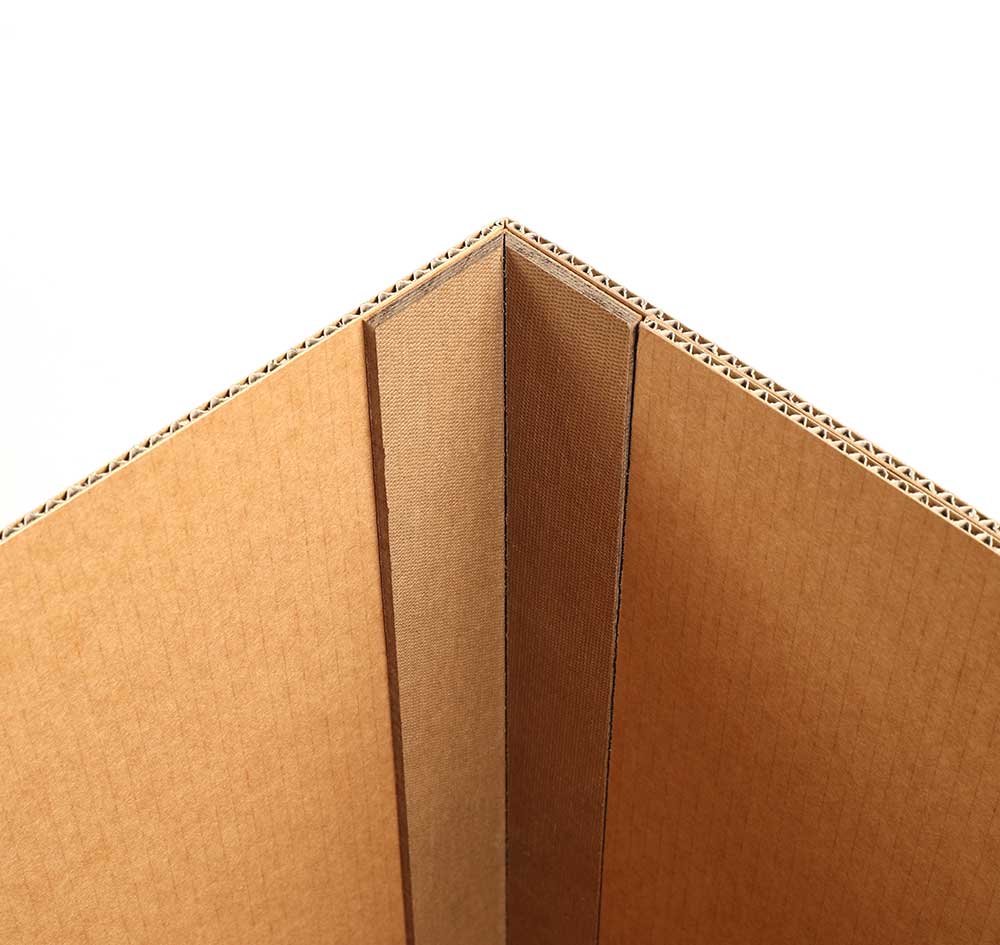

Why is Strawboard strong?

Nefab EdgePak Straw evolved out of our corrugated solution. We wanted to develop a quick-and-easy solution with lower cost and increased stacking strength. The compact, wet mechanical process makes straw pulp more resistant to moisture than paper. The straw fibers are short (not flexible) but very stiff compared to wood fiber, when combining the layers it gives the material great strength.

Nefab Strawbased Solutions from NefabTV on Vimeo.

Award winning application for Lithium-Ion Batteries

Background

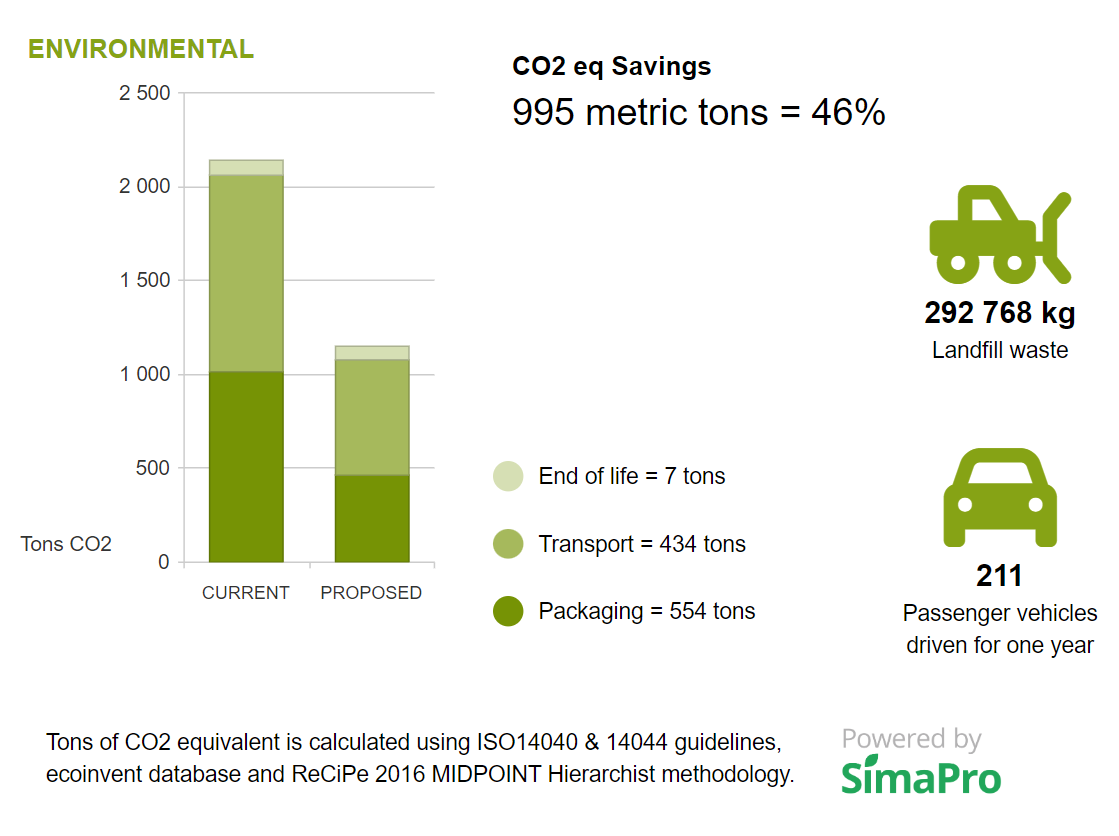

Nefab was contacted by a company with the goal of improving their supply chain. Their customer, the 4th largest car manufacturer, requested them to eliminate the expendable Expanded Polypropylene (EPP) trays currently used to transport battery modules from China to Europe. The EPP tray’s recycling cost and environmental impact were both unacceptable to them.

Our Solution

As a solution to the request, our engineers in China developed a design almost entirely made of paper. The new solution was based on EdgePak Straw, corrugated and paper pulp fitments.

The EdgePak Straw design provides enough strength to pass the UN certification and allowed 1+3 stacking with over 350 kg per box. The packaging solution is UN certified to meet the demands for transporting LiBs.

Customer Benefits

Our EdgePak straw solution was able to reduce customer’s environmental footprint and improve their financial savings. In terms of CO2, the savings amounted to more than 1000 metric tons per year

How to Recycle EdgePak

At Nefab, we're committed to reducing our environmental impact and contributing to a more circular economy. That's why we've invested in researching the repulpability of our fiber-based solutions. We've partnered with two of the top laboratories in the field, PTS Lab Germany and Michigan State University, to conduct rigorous testing and analysis of our products.

Through this, we've developed our solutions able to be recycled in the paper waste stream. Key steps are the grinding and soaking recycling step. This enables us to partner with recyclers and ensure we meet the highest sustainability recycling standards.

Our collaboration with PTS and Michigan State University is just one example of how we're taking action to achieve our sustainability goals. Of course we also made complete life cycle analyses of our fiber-based materials and know their CO2 eq. and other impact categories in detail.

PTS Report | Michigan State Report

For all types of applications

EdgePak straw can be used for a wide variety of applications, ranging from light to heavy. It can be used to ship products through road, sea and air. It can be custom made with different styles of lids, corrugated sleeves and pallets to match the needs of your products.

Easy to assemble

EdgePak Straw is easy to assemble, and provides full accessibility from front side, which makes it easy to load and unload.

Customizable

EdgePak can be custom made with differents styles of lids and and pallets to match the needs of your products.

Sustainable Solution

With EdgePak Straw you get both a strong and sustainable solution that can be recyled as easy as a sheet of paper anywhere in the world.

For more information

Contact us for more information about our EdgePak Solutions