The global push to eliminate plastic waste, particularly from packaging, has gained significant traction, with plastics accounting for around 36% of all materials used in packaging 1. Unfortunately, about 85% of these plastics end up in landfills or as unregulated waste2. Many single-use plastic packages are not designed to be recycled, leading to less than 10% of the seven billion tonnes of plastic waste generated worldwide being reused3. In response, consumers and companies are turning towards alternative materials that are viewed as more sustainable. However, transitioning to alternative packaging, especially for heavy-duty or fragile telecom equipment, is a complex task. It requires innovative solutions that can protect products during transit while also addressing sustainability goals.

In the telecom industry, where connectivity is essential, equipment is often installed in remote and challenging locations, such as mountain peaks, forests, and deserts. As the network infrastructure expands into these areas, the demand for durable, biodegradable packaging that can withstand the stresses of transportation without harming the environment grows. Packaging must not only safeguard equipment but also be designed with end-of-life considerations, ensuring it is either recyclable within local waste streams or completely biodegradable, especially in regions where waste disposal options are limited. How can we transition to innovative alternatives to virgin plastic that are both durable and environmentally responsible?

Innovative Packaging Design

Eliminating virgin plastic packaging from telecom supply chains requires a shift toward innovative, fully recyclable materials. This transformation relies heavily on the expertise of packaging engineers who design and test new solutions that meet environmental responsibility standards while ensuring the protection of increasingly delicate telecom equipment. Transitioning to alternative packaging, especially for heavy-duty or fragile electronics, is a complex process. Packaging must be durable enough to withstand the rigors of transportation from production facilities to remote installation sites while still being environmentally friendly. Such new materials undergo rigorous testing to ensure they can protect sensitive equipment during transit. In today’s global supply chain, it is also important to ensure that new packaging materials are readily available across the globe.

Understanding what happens to packaging materials after use is critical to building a sustainable future. Recycling not only helps minimize waste but also conserves raw materials and energy, reducing the overall environmental impact. Packaging that is designed for recyclability ensures that valuable resources can be reintroduced into the supply chain, rather than ending up in landfills. Moreover, recycling reduces the demand for virgin materials, lowering carbon emissions associated with extraction and manufacturing processes. By prioritizing biodegradable, recyclable or reusable packaging, companies not only meet growing regulatory requirements but also align with consumer expectations for more environmentally responsible solutions. In turn, this fosters a more circular economy, where materials are continuously repurposed, driving both sustainability and cost efficiency.

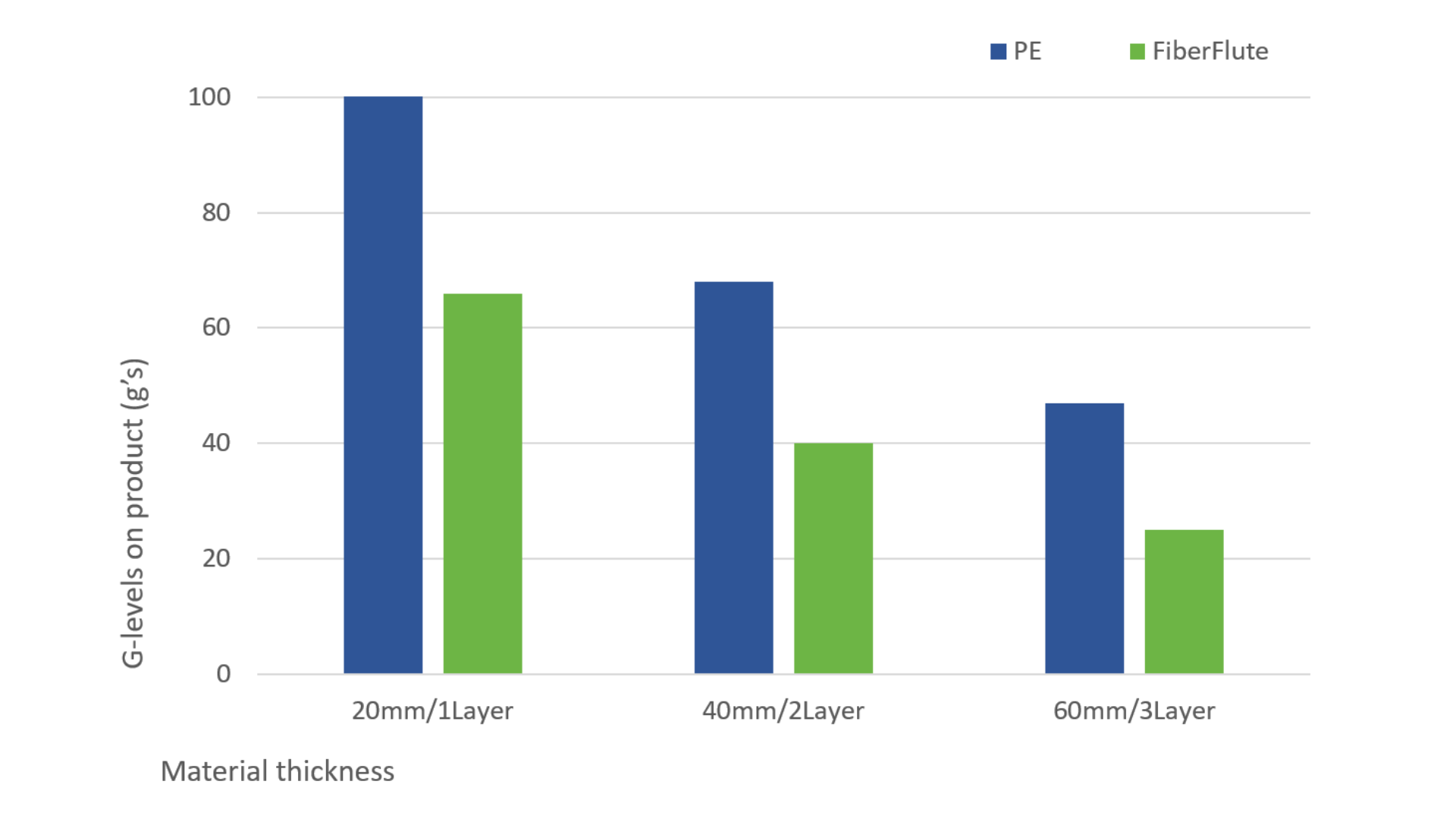

A comparative analysis between PE foam (30kg/m³) and Nefab’s FiberFlute showed that FiberFlute has 40-45% lower G-values. This indicates that less material is needed with FiberFlute to achieve the same level of protection for products compared to PE foam.

Sustainable Fiber-Based Solution

In the telecom sector, where equipment is often transported to remote and difficult-to-reach locations, such as mountain tops or isolated antennas, packaging must either be fully recyclable in the available waste stream or completely biodegradable. Fiber-based solutions can be effectively processed in the available waste streams, even in areas with limited disposal options. This is why they are an effective alternative to single-use plastics. By leveraging the natural strength of both fresh and recycled fibers, these materials provide durable protection while minimizing the use of natural resources. Fresh fibers offer superior strength, making them ideal for demanding supply chains, such as when heavy telecom equipment is shipped overseas. The lighter weight of fiber-based packaging reduces the environmental impact and overall costs, especially in air transport where weight is a critical factor.

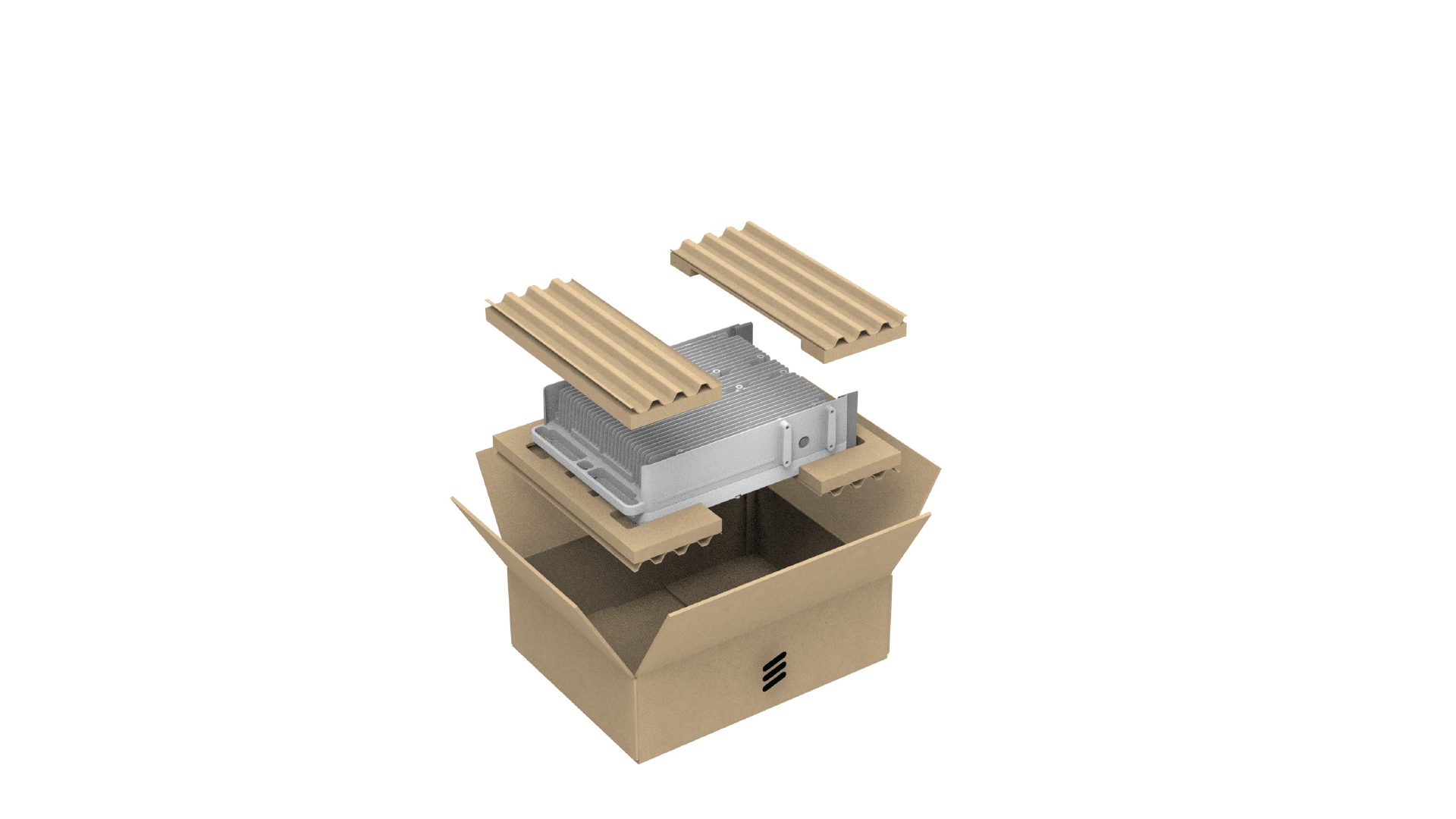

A prime example of the benefits of fiber-based solutions comes from Ericsson, which transitioned from single-use plastics to fully recyclable fiber-based packaging inserts for their Remote Radio units 4. These inserts include an anti-abrasion coating to protect the product during shipment without requiring additional plastic bags. With the ability to withstand up to 36 kg of load, Ericsson’s fiber-based packaging maintained product protection, quality, and functionality, while significantly reducing plastic content from 20% to less than 1%. Moreover, the packaging size was reduced by 15-20%, further lowering environmental impact and costs. This shift is aligned with Ericsson’s Net Zero mission, showcasing how fiber-based solutions can support both sustainability and operational efficiency in the telecom supply chain.

By switching to fiber-based packaging materials, Ericsson Remote Radio products are fully recyclable and reduce total plastic content from 20% to less than 1%. (Source: Ericsson)

More Connected and Sustainable Future

The drive to eliminate plastic waste in packaging is reshaping industries worldwide, and the telecom sector is no exception. As the demand for environmentally responsible solutions grows, transitioning from single-use plastics to fiber-based packaging presents a promising path forward. By embracing innovative, recyclable, and biodegradable materials, telecom companies can significantly reduce their environmental footprint while ensuring robust protection for sensitive equipment. The success of fiber-based solutions highlights the potential for sustainable packaging to meet both operational and environmental goals. As the industry continues to navigate the challenges of remote installations and stringent sustainability targets, adopting advanced packaging solutions will be crucial in achieving a greener and more efficient future.